The exterior appearance of the garage doors may be similar to that of the residential and commercial premises, but the parts that facilitate the doors to fulfill their functions are designed to address extremely different needs. The residential ones are typically focused on the comfort of daily existence, the commercial ones on power, durability, and resilience in the process of constant operation. Their differences are necessary to select the right garage door part or Residential Garage Door Parts for a specific task, which will guarantee the safety of the component and its longevity. These differences affect such aspects as door size and materials, power of springs, tracks, and operators needed to work smoothly.

Door Size, Weight, and Material

The size and weight of the commercial and residential garage doors are the most striking difference between the two types. Garage doors of houses are usually structured to suit the normal home garage and are meant to suit cars and mini storage. Lightweight steel, aluminum, composite woods, and fiberglass are also among the building materials they use, and they can easily operate, and their hardware demands less strain.

Commercial doors are much bigger, and they are designed to meet the challenging conditions of warehouses, factories, delivery centers, fire stations, and storage centers. These doors have to endure heavy traffic and large quantities of cycling, and therefore, weight factors are a great consideration.

Hardware Components Strength and Durability

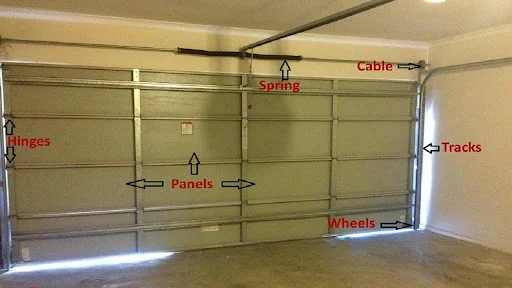

The equipment that is involved in residential garage door systems is adequate to support moderate usage in the day-to-day activities. The use of rollers, hinges, and brackets is used in order to support the lesser weight of home garage doors and to withstand the general usage pattern of the homeowners. Average residential doors are opened a few times a day, which does not require an industrial-grade load capacity of the hardware.

Hardware used by commercial garage doors is designed to be used much more heavily. The environments come with a high frequency of opening and closing throughout the day, which puts them under constant strain on all parts. Thick steel hinges, reinforced brackets, industrial-strength rollers, and high-quality bearings are necessary to ensure a consistent performance. These parts should also be operating in adverse environments, such as dust, moisture, changes in temperature, and high vibration.

Springs and Counterbalance Systems Differences

Springs constitute some of the most significant elements of any garage door system, as the majority of the weight of the door is carried on them, and the door is able to rise and descend without any problems. Small to medium torsion springs or extension springs are mostly used with residential garage doors. These springs have a moderate number of cycles, and they can be used in a common domestic setting.

Garage doors used in commerce require more robust spring systems. Commercial doors have torsion springs, which are bigger, sturdier, and can handle loads that are very heavy. They also have a more purposeful cycle life since the commercial doors could run hundreds of opens and closes each day. The weight is shared with multiple torsion springs, which are used to work together and provide more safety in many commercial systems.

Track Arrangements and Strengthening Demands

Tracks of residential garage doors are designed in a relatively standard format since the home garage sizes are usually the same. These doors are manufactured using less dense steel that is powerful enough to hold a typical residential load. The construction is typically an arrangement of vertical tracks to run the door upwards and horizontal tracks to keep the door resting in the air when open.

Track designs need to be more specialized and extra-reinforced to support commercial doors. The tracks are also made of heavy-gauge steel to support the weight and height of large doors. At the industrial level, the doors might be required to move vertically or at an angle, which utilizes the maximum amount of ceiling space. This has led to high-lift or full vertical-lift systems frequently found in commercial track systems. This arrangement also involves reinforcement of such setups, brackets, and supporting hardware so as to maintain the system stable over time under continuous pressure.

Functional Differentiations and Strength Need

Garage door openers are residential devices that are convenient. They are designed to be quiet and smooth and may include such functionality as remote controls, mobile applications, and smart home connectivity. These operators use lightweight doors, and hence, the motors do not require very high horsepower.

The commercial garage door operators have to offer considerably higher power. These openers have heavy-lifting motors, which are meant to be used frequently. A lot of the commercial doors work in such an environment where speed and reliability are important, as opposed to the reduction of noise. The Industry and warehouses usually need operators who can work around the clock without overheating or slacking.

Installation Issues and Maintenance Requirements

The process of installing a garage door at home is not very difficult since the sizes are standardized, and the mechanisms are not new. Home installations require less heavy equipment and, in most cases, take a short time to finish. It is also limited by the maintenance requirements because residential systems are not subjected to intensive operation. Routine lubrication and frequent replacement of parts tend to make a home garage door perform well over a long period of time.

The installation of commercial garage doors is a more complicated process because of the weight, size, and special equipment. It must be professionally knowledgeable in order to achieve the right alignment of tracks, springs, and reinforcement systems. Safety is one of the key factors, because the slightest errors in installations can lead to dangerous circumstances.

Expectancy of Performance in Both Environments

There is also a significant difference in the expectations of performance between commercial and residential garage doors. The consumer usually focuses on style, silence, and longevity. The components employed will have a lifetime of a few years with minimal maintenance.

Business users are very functional, expect durability and reliability during constant usage. It focuses on the equipment that can withstand the harsh environment and still retain efficiencies in operations without breaking down very often. That is why commercial parts will always have a higher level of performance, although they might need to be checked and fixed more often.

Conclusion

Despite the fact that the commercial and residential garage door systems are designed to perform the same fundamental role, the dissimilarity between the systems is very high in terms of their parts. Homes are more moderate in their usage and need less powerful equipment and less complicated mechanisms. Commercial systems, on the other hand, require power, robustness, and capability to operate under strenuous workloads, and this necessitates hi-tech hardware, fortified tracks, muscular springs, and commercial operators. The knowledge of such differences enables facility managers and installers, as well as homeowners, to select the appropriate components in every environment, resulting in safety in the long term, efficient functioning, and dependable performance.

Discover more reads designed to expand knowledge, boost skills, and inspire action now.