In the ever-evolving world of manufacturing and production, the demand for precision and efficiency is paramount. One technology that stands out in addressing this demand is laser cutting. This advanced method has transformed the way industries operate, offering unparalleled accuracy and speed.

Understanding Laser Cutting Technology

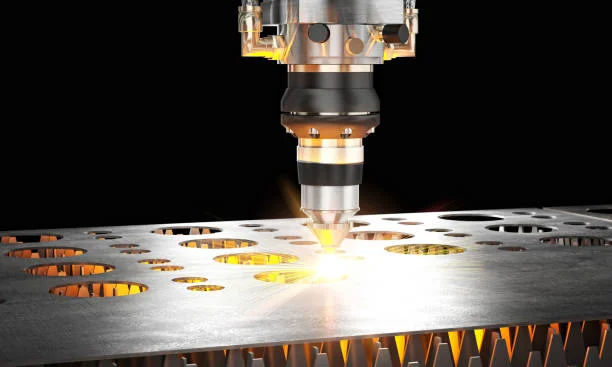

Laser cutting technology utilises a high-powered laser beam to cut and engrave various materials. It operates by focusing the laser beam into a small spot with immense energy density. As the laser interacts with the material, it either melts, burns, or vaporises the target area, resulting in precise cuts.

The versatility of laser cutting is evident in its application across numerous industries. From automotive to jewellery production, the technology facilitates intricate designs and complex components with ease. Its adaptability makes it a go-to solution for manufacturers aiming to enhance productivity while maintaining high-quality outputs.

Don’t miss the highlight—our Featured Post leads the conversation today!

The Benefits of Advanced Laser Cutting

Advanced laser cutting technology offers numerous benefits that traditional cutting methods cannot match. Firstly, it ensures high precision, allowing for the creation of detailed and intricate designs. This level of accuracy significantly reduces material wastage, contributing to cost-effective production processes.

Another advantage is the efficiency of the cutting process. Laser cutting can achieve faster cutting speeds than conventional methods. This speed is crucial for meeting tight production schedules without compromising on quality. Moreover, the automation capabilities of modern laser cutting machines minimise the need for manual intervention, further enhancing productivity.

Materials Suitable for Laser Cutting

One of the outstanding features of laser cutting is its ability to cut through a wide range of materials. These include metals, plastics, wood, glass, and textiles. The choice of material largely depends on the specific application and the desired outcome.

In automotive industries, for instance, laser cutting is utilised for cutting metals and composites, crucial for manufacturing high-performance components. Jewellery makers, on the other hand, benefit from the precision of laser cutting when working with precious metals and gemstones, allowing for exquisite designs.

Innovations in Laser Cutting Technology

As technology continues to advance, laser cutting has seen significant innovations. These developments have led to more efficient and environmentally friendly processes. New laser technologies, such as fibre lasers and CO2 lasers, enhance cutting efficiency and material compatibility.

Fibre lasers are particularly noteworthy due to their energy efficiency and ability to cut reflective materials like copper and aluminium. CO2 lasers, known for their precision, are commonly used for non-metal materials, expanding the scope of laser cutting applications.

Impact of Laser Cutting on Manufacturing Industries

The impact of laser cutting on manufacturing industries is profound. One of its primary contributions is the drastic reduction in lead times. By accelerating the production process, industries can adapt quickly to market demands, providing them with a competitive edge.

The precision of laser cutting also enhances product quality, resulting in fewer defects and improved customer satisfaction. As a result, companies are able to maintain high standards while operating cost-effectively, ultimately leading to increased profitability.

The Future of Laser Cutting

Looking ahead, the future of laser cutting technology appears promising. With ongoing research and development, the capabilities of laser cutting machines are expected to expand further. One area of focus is the integration of AI and machine learning, which promises to elevate the efficiency and accuracy of laser cutting operations more significantly.

In addition, the push towards sustainability is likely to influence the development of laser cutting technologies. Energy-efficient systems and environmentally friendly practices will become priorities, ensuring that the industry continues to grow responsibly.

Choosing the Right Laser Cutting Service

For companies looking to benefit from laser cutting, selecting the right service provider is crucial. Considerations include the provider’s expertise, the range of materials they can handle, and their ability to deliver quality work on time.

Laser Central Pty Ltd (t/a Laser Central) offers state-of-the-art laser cutting services tailored to meet the diverse needs of various industries. With a focus on precision and efficiency, they ensure that clients receive top-notch outcomes.

Conclusion

Advanced laser cutting technology is a game-changer for industries striving to balance precision, efficiency, and cost. Its ability to cut through a broad spectrum of materials with exceptional accuracy has revolutionised production processes. As innovations continue to shape the landscape, laser cutting will undoubtedly remain at the forefront of technological advancement, driving growth and efficiency in the manufacturing sector.

Don’t miss the highlight—our Featured Post leads the conversation today!