The difference between securing your laneway suite permit smoothly and facing months of regulatory headaches often comes down to one thing: understanding what municipal reviewers actually look for when evaluating a laneway suite permit application. Blueprint Revolution same principle applies whether you’re planning a compact urban addition or designing a sprawling manufacturing complex. The connection might not be immediately obvious, but the permitting process for industrial facilities and residential expansions shares more DNA than most realize.

Picture this: you’ve spent weeks perfecting your facility design, invested in cutting-edge equipment specifications, and assembled a dream team of contractors. Then reality hits when the permitting office sends back your application with a laundry list of revision requests that could derail your timeline. Sound familiar? It happens more often than the construction industry cares to admit, costing businesses millions annually in delayed launches and missed market opportunities.

Why Permits Matter More Than Your Bottom Line Calculation

Here’s something contractors learned the hard way during the 2020s construction boom: cutting corners on permit documentation doesn’t just risk legal trouble; it fundamentally compromises your facility’s long-term viability. Think of permits like the operating system on your phone. Sure, you could probably jailbreak it and bypass the safeguards, but you’d be sacrificing stability, security, and the Blueprint Revolution ability to actually use the thing for its intended purpose.

When manufacturing facilities skip proper permitting for “speed,” they’re essentially building on quicksand. One fire marshal inspection away from a shutdown order. One zoning complaint from becoming a very expensive renovation project. The permitting process, tedious as it feels, acts as quality control for your entire operation’s foundation.

The Hidden Economics of Getting It Right

Consider this scenario playing out across industrial parks nationwide: Company A rushes through permits with minimal documentation to break ground three months early. Company B takes the extra time, hires experienced drafting services, and submits comprehensive plans that address every potential concern upfront. Fast forward 18 months.

Company A has faced two stop-work orders, three major redesigns, and countless delays from inspectors finding code violations that should have been caught during planning. Their “three-month advantage” became a nine-month deficit, plus the costs of rework that could have funded an entirely new product line.

Company B? They’re six months into profitable operations, their facility running exactly as designed, with zero unexpected compliance issues. Their comprehensive permit drawings eliminated ambiguity before the first foundation pour.

Where Industrial Design Meets Regulatory Reality

The most successful facility designers think like chess players, anticipating regulatory moves several steps ahead. They know that modern industrial permitting isn’t just about meeting minimum standards; it’s about demonstrating how your facility contributes to safer, more sustainable industrial development.

Blueprint Revolution mindset shift changes everything. Instead of viewing permits as obstacles, forward-thinking developers treat them as strategic tools for de-risking projects and accelerating approval timelines.

Loading Bay Configuration might seem straightforward until you factor in traffic flow studies required by most municipalities. Your brilliant design with twelve loading docks becomes a permitting nightmare if you haven’t mapped how twenty delivery trucks navigate your parking lot simultaneously during peak hours. Industrial drafting services worth their fees will model this scenario before you submit applications, not after the planning commission requests it.

Ventilation and Environmental Controls represent another area where proactive planning pays dividends. Modern manufacturing often involves chemical processes, heat generation, or particulate emissions that trigger environmental review thresholds. The facilities that breeze through environmental permitting have already commissioned air quality modeling, noise impact studies, and mitigation plans as part of their initial documentation package.

Utility Infrastructure Planning separates amateur facility designs from engineered masterpieces. Your 50,000-square-foot warehouse needs how much electrical capacity? What about water supply for fire suppression systems that building codes mandate for your industry classification? Smart designers coordinate with utility providers during the planning phase, securing service agreements before permits get submitted. This prevents the nasty surprise of discovering the local grid can’t handle your load after you’ve already invested in site preparation.

The Drafting Difference That Actually Matters

Here’s what separates adequate facility drawings from permit-accelerating documentation: specificity that answers questions before reviewers ask them.

Generic floor plans showing walls and doors? That’s baseline. What reviewers actually need includes detailed annotations explaining material specifications, load calculations for storage areas, emergency egress routes with distance measurements, ADA compliance features, and integration with existing infrastructure. The difference between “bathroom” labeled on a plan versus comprehensive plumbing details with fixture specifications, water pressure calculations, and waste line routing isn’t just thoroughness; it’s the difference between approvals and revision requests.

Industrial facilities face even higher documentation standards. Your manufacturing equipment creates vibration? Show the structural engineering calculations proving your floor can handle it. Planning to store hazardous materials? Include the safety systems, containment specifications, and emergency protocols in your permit set. These aren’t optional extras; they’re what separates applications that sail through committees from those languishing in review purgatory.

Learning From Residential Innovations

Interestingly, the residential laneway suite boom has pioneered documentation techniques now migrating to industrial applications. Small-footprint laneway developments forced designers to maximize efficiency within tight constraints, leading to innovative approaches for demonstrating compliance in space-limited scenarios. Blueprint Revolution same techniques apply when retrofitting existing industrial buildings or maximizing warehouse capacity.

The prefabrication documentation methods perfected for laneway suites, where entire units arrive substantially complete and just need site connection, increasingly influence industrial facility construction. Modular clean rooms for pharmaceutical manufacturing or prefabricated electrical rooms for data centers follow similar approval pathways as residential ADUs.

Technology Reshaping the Permitting Landscape

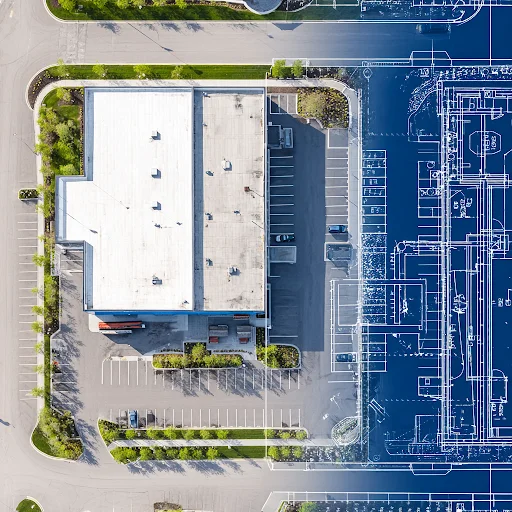

Three-dimensional modeling has revolutionized how facilities navigate approval processes. When planning departments can virtually walk through your proposed warehouse, understanding spatial relationships and code compliance becomes intuitive rather than abstract. Blueprint Revolution visual clarity accelerates reviews by eliminating ambiguity.

Building Information Modeling (BIM) takes this further by embedding compliance data directly into 3D models. Fire-rated walls automatically flag themselves. Egress paths calculate distances in real-time. Code violations get caught by software before human reviewers ever see plans. The facilities leveraging these tools report 40% faster permit approvals compared to traditional 2D documentation methods.

Cloud-based collaboration platforms enable real-time coordination between designers, engineers, and permitting authorities. Questions that once triggered weeks of correspondence now get resolved in hours through shared digital workspaces. This velocity advantage compounds throughout project timelines, especially on complex facilities requiring multiple agency approvals.

Strategic Timing and Phasing Considerations

The smartest facility developers think strategically about permit sequencing. Rather than submitting one massive application for an entire complex, they phase submissions to maintain forward momentum even when specific elements face delays.

Your core manufacturing space might require straightforward industrial permits that process quickly, while specialized laboratories or hazardous material storage trigger environmental reviews taking months. By separating these into distinct permit applications, construction begins on foundation and structure while specialized spaces await their specific approvals. This parallel processing shaves months off timelines without compromising thoroughness.

Pre-application meetings with planning departments represent perhaps the highest-ROI time investment in the entire process. These informal sessions let designers present concepts and gauge regulatory reception before investing in full documentation. Experienced permit navigators use these meetings to identify potential concerns early, when addressing them is still cheap and fast.

Building Relationships That Matter

The most successful industrial developers maintain ongoing relationships with permitting authorities rather than treating them as adversaries encountered only during applications. They attend planning commission meetings even when their projects aren’t being discussed, volunteer for industry advisory committees, and position themselves as partners in thoughtful development rather than obstacles to overcome.

Blueprint Revolution relationship-building pays tangible dividends when unique situations arise. The facility designer who regularly engages with code officials has built credibility that helps when requesting variances or proposing innovative solutions not explicitly covered by existing regulations. They’ve demonstrated good faith and competence, making reviewers more receptive to creative approaches.

Where Facility Planning Meets Business Strategy

The most sophisticated facility developers integrate permit strategy into business planning from day one, not as an afterthought once designs are complete. This means:

- Selecting sites with pre-existing favorable zoning classifications

- Timing applications to align with municipal budget cycles when reviewer capacity is highest

- Structuring phased developments to maintain construction momentum through inevitable delays

- Building contingency timelines that account for realistic permitting durations rather than wishful thinking

Facilities delivered on time and budget increasingly reflect this strategic integration. The era of “design it, then figure out permits” has given way to “design with permits in mind from conception.” This shift doesn’t constrain creativity; it channels innovation toward solutions that work in the real world of regulatory compliance.

The Competitive Advantage of Getting It Right

In today’s ultra-competitive industrial real estate market, facilities that navigate permitting smoothly gain decisive advantages over slower competitors. First-mover benefits in emerging markets, ability to meet contractual deadlines with key customers, and financial predictability that preserves capital for growth rather than overrun management all flow from permit mastery.

The companies dominating their industrial niches share this common thread: they view regulatory compliance as a competitive moat rather than a cost center. Their facilities reflect this philosophy in every detail, from documentation quality to community engagement strategies that smooth approval pathways.

Smart facility planning isn’t about cutting corners or gaming the system. It’s about understanding that permits represent a critical quality control checkpoint protecting your long-term operational success. Whether you’re adding a laneway suite to generate rental income or constructing a manufacturing campus to launch your next product line, the principles remain consistent: thorough documentation, proactive communication, and strategic planning transform permitting from obstacle to advantage.

Featured highlights—posts designed to deliver insight and actionable value.