Introduction: A $100,000 Mistake in Sourcing

Imagine you’re the purchasing manager for an industrial equipment manufacturer. You just secured a new supplier offering stainless steel at a competitive price, labeled simply as “304 stainless steel.” Fast forward three months, your product arrives at the client site, and within weeks, rust spots appear, leading to a costly recall costing your company over $100,000. Your professional reputation takes a hit, and trust is lost—all due to misunderstanding the difference between two common steel standards: SS304 and SUS304.

While both SS304 and SUS304 are widely known forms of stainless steel, subtle differences between them can create substantial problems for buyers unfamiliar with the details. Understanding these distinctions early is crucial for preventing costly sourcing errors.

In this guide, we’ll clearly outline the critical difference between SS304 and SUS304, explain why these nuances matter so much in procurement, and offer practical guidelines for buyers to verify material quality. Lastly, we’ll discuss how to select a reliable manufacturing partner, particularly if you’re sourcing from Asia.

What’s the Real Difference Between SS304 and SUS304?

First, let’s clarify a common confusion: SS304 refers to the American ASTM standard, whereas SUS304 corresponds to the Japanese JIS standard. Although chemically similar, their subtle differences in standards, measurement methods, and documentation can significantly affect your procurement decisions.

- SS304 (ASTM A240) typically defines stricter requirements for tensile strength, yield strength, and precise chemical composition. It’s commonly specified in industries where certification and documented performance under rigorous standards are necessary—like medical devices, aerospace components, and certain automotive parts.

- SUS304 (JIS G4305), although similar, generally has slightly looser tolerances for mechanical properties. It is often selected for more general-purpose applications, primarily in the Asia-Pacific region.

Misinterpreting these two standards can result in purchasing steel with insufficient mechanical performance or unexpected corrosion resistance issues. That’s why understanding the difference between SS304 and SUS304 isn’t just technical trivia—it’s essential risk management for any global buyer.

Why Do These Subtle Differences Matter to Buyers?

When suppliers label stainless steel merely as “304,” the hidden risk is that you might unknowingly receive SUS304 instead of SS304, or vice versa. While for some applications, this difference might seem negligible, in critical applications such as medical equipment or precision instruments, even minor variations can be catastrophic.

For example, a European medical device manufacturer once specified SS304 for its surgical instruments but inadvertently sourced SUS304. The subtle chemical differences meant the steel lacked the documented corrosion resistance required for medical certifications in the EU, causing the entire batch to be rejected.

As a buyer, this underlines the importance of explicitly stating the required standard—ASTM or JIS—in your procurement documents and ensuring your supplier explicitly confirms these details.

Related insight: This article dives even deeper into the topic.

How to Verify the Quality of SS304 and SUS304 Effectively

Given the stakes, verification of the steel’s standard and quality before acceptance is essential. Here’s a practical checklist to help procurement professionals:

- Material Test Reports (MTR):

Always demand comprehensive MTRs specifying exact chemical compositions (chromium, nickel, carbon percentages) and mechanical properties like tensile and yield strengths. - Third-Party Laboratory Testing:

For critical applications, independently verify materials by sending samples to accredited labs for spectroscopic analysis and mechanical tests. - Packaging and Label Inspection:

Confirm packaging labels explicitly state ASTM A240 or JIS G4305, along with traceable batch numbers. - Quality Assurance Audits:

Implement periodic QA audits and random spot checks at your supplier’s facility, ensuring continuous compliance and transparency.

This structured verification significantly reduces the risk of costly material mismatches.

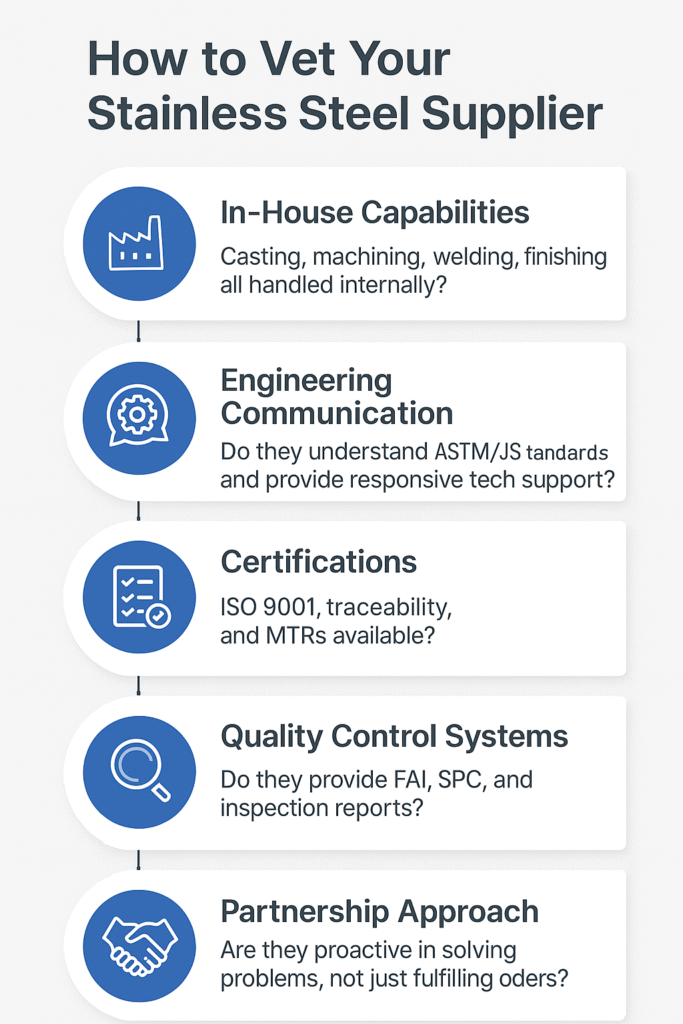

Selecting the Right Stainless Steel Manufacturing Partner

Choosing the correct steel grade is important, but equally crucial is selecting a reliable manufacturing partner who can consistently deliver quality and compliance. Especially when sourcing internationally, choosing based solely on price can lead to significant hidden costs later. When evaluating potential suppliers, consider these criteria carefully:

Integrated Manufacturing Capabilities

Look for suppliers who manage critical processes—such as casting, machining, welding, and surface finishing—in-house. Full-service partners help reduce handoffs, delays, and quality inconsistencies. One example is CSMFG manufacturing in Asia, known for offering end-to-end production capabilities under one roof, which enhances coordination and accountability throughout the supply chain.

Proven Technical Communication

Ensure suppliers have multilingual, technically proficient engineering teams who clearly understand international standards (ASTM, JIS, EN) and can respond quickly to your design or compliance queries.

Certifications and Traceability

Verify that the supplier provides complete documentation, including ISO certifications and detailed traceability records. This is critical for audit readiness and long-term quality assurance.

Transparent Process Control

Trustworthy manufacturers implement strong quality control systems, such as First Article Inspection (FAI), Statistical Process Control (SPC), and full material traceability—from raw input to finished product.

By choosing a partner with deep engineering capabilities, responsive communication, and proven quality systems, you not only lower operational risk—you set your project up for scalable, long-term success.

Real-World Example: The True Cost of a Poor Supplier Match

A North American automotive supplier sourced stainless steel fasteners labeled simply as “304” from an unknown overseas vendor, attracted by a low price. Weeks after installation, corrosion emerged, forcing the company into a costly recall, and damaging their reputation.

Investigation revealed that the supplier had used SUS304, meeting local standards but not the stringent ASTM specifications required by the automotive brand. Had the company clearly specified and verified SS304 ASTM standards and worked with a reliable manufacturer offering documented certification, this costly fiasco could have been avoided.

Final Checklist for Buyers: Ensuring Stainless Steel Success

Before finalizing your stainless steel procurement, always follow this simplified but effective checklist:

- Clearly state the exact standard required (ASTM or JIS) in your RFQs and purchase orders.

- Insist on Material Test Reports (MTRs) and verify them rigorously.

- Conduct independent third-party testing for critical applications.

- Perform thorough onsite quality assurance audits periodically.

- Choose a supplier offering comprehensive manufacturing capabilities, reliable certifications, and clear communication lines, such as CSMFG manufacturing in Asia.

Conclusion: Smart Buyers Choose Standards and Partners Wisely

In stainless steel procurement, small oversights can lead to significant consequences. Clearly understanding the difference between SS304 and SUS304 is foundational, but equally crucial is choosing the right manufacturing partner. Integrating rigorous material validation and strategic supplier evaluation ensures your procurement strategy not only meets your specifications but also protects your bottom line and company reputation.

Be proactive, detail-oriented, and selective—because your choice today defines your product’s success tomorrow.

There’s plenty more where that came from—browse our other helpful content!