Optimized packaging helps cut costs, save time, and reduce waste. It also improves workflow and boosts delivery speed. Every part of the process matters.

From materials to machines, small changes make a big impact. Smarter packaging means better results. It’s key to staying competitive. Strong packaging strategies lead to fewer delays and better customer satisfaction.

Use this guide to apply optimized packaging in your operations.

Assessing Packaging Needs and Materials

The first step is reviewing what products are being packaged and how they move through the system. Size, weight, and fragility should all be considered. Using the right materials can cut waste and lower shipping costs.

Overpacking wastes resources while underpacking risks damage. It’s important to match packaging type to product needs. Regular assessments help avoid unnecessary complexity.

Simplifying the Packaging Process

Too many steps slow things down. Streamline how products are boxed, sealed, and labeled. Set clear procedures for teams to follow and reduce unnecessary touchpoints.

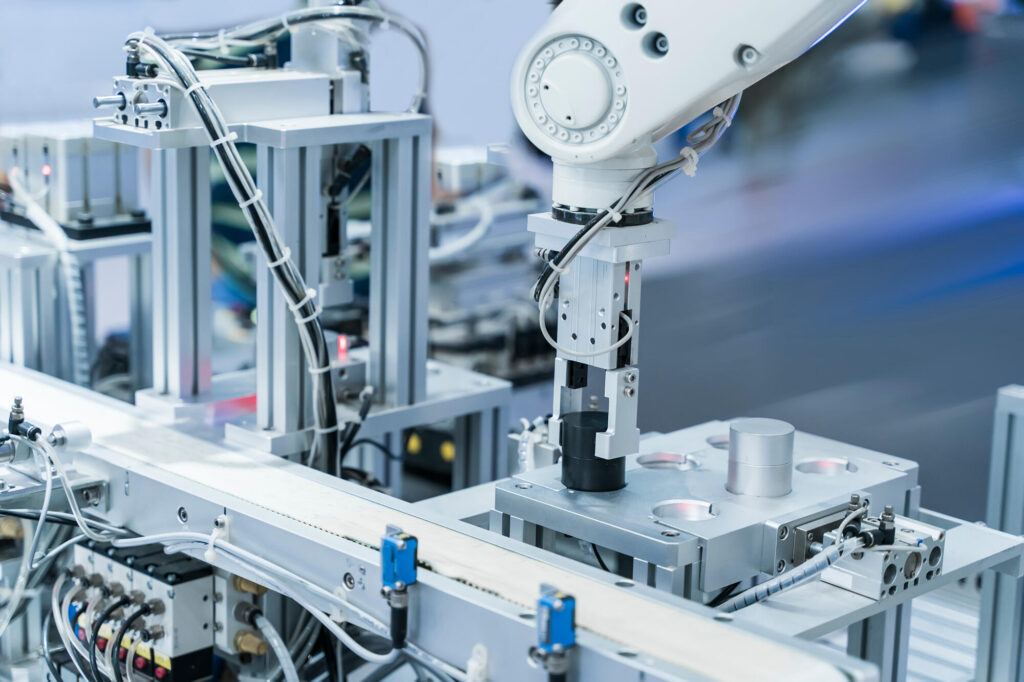

Consistency makes training easier and boosts output. Use automation when possible to keep things fast and accurate. A form fill seal packaging machine is one example that supports streamlined, consistent results.

Reducing Packaging Waste

Waste reduction starts with better planning. Choose packaging that uses less material without compromising protection. Reuse materials where possible and recycle what can’t be reused.

Design with sustainability in mind to limit landfill impact. Avoid mixed materials that are hard to separate. Less waste means lower costs and better environmental compliance.

Improving Workflow Efficiency

Packaging should fit smoothly into the overall workflow. Delays often happen when packing is disconnected from the rest of the process. Align packaging steps with inventory, picking, and shipping.

Keep everything organized to avoid backlogs. Staff roles should be clearly defined. Efficient workflows save time and keep orders moving without interruption.

Enhancing Storage and Transport

Optimized packaging also means easier storage and safer transport. Box sizes should match shelf and truck dimensions to avoid space loss. Stackable designs help with warehouse efficiency.

Lighter packaging cuts fuel use and shipping fees. Good labeling makes handling easier and faster. All these small wins add up to significant savings over time.

Monitoring and Continuous Improvement

Once changes are in place, they should be reviewed regularly. Track performance with data like packaging time, error rates, and material usage. Use feedback from workers and customers to refine the system.

Set benchmarks and aim for steady gains. Stay updated on new materials and methods. Continuous improvement ensures long-term success in packaging efficiency.

Training Staff for Smarter Packaging

People handling packaging must know what to do, fast and right. Simple steps help them work better. Train them on materials, machines, and packing rules.

Use short guides and repeat practice. Make sure everyone does it the same way. This avoids mistakes and saves time daily.

Invest in Optimized Packaging

Optimized packaging drives better performance across the board. It cuts costs, improves delivery, and reduces waste. By focusing on smarter materials, smoother workflows, and ongoing review, companies can gain a real edge.

The goal is not just to pack faster but to pack smarter. With every step refined, the entire operation benefits.

Should you wish to read more, explore our blog.