A pneumatic engraver is a precision tool designed for long-term use, but like any frequently used equipment, its appearance and performance can gradually decline without proper care. Dust buildup, surface wear, internal residue, and neglected maintenance can all affect how the tool looks and functions over time. Fortunately, with the right care routine, it is possible to restore both the appearance and efficiency of your pneumatic engraver, giving it a fresh new look and extending its working life.

This guide focuses on practical, reliable methods for caring for your engraver, maintaining aging components, and ensuring that your tool continues to perform consistently after extended use.

Why Regular Care Matters for a Pneumatic Engraver

Many users focus only on performance issues, but appearance and function are closely connected. A pneumatic engraver that is clean, properly lubricated, and well-maintained not only looks better but also operates more smoothly. Dirt and residue can interfere with airflow, increase internal friction, and cause uneven engraving results.

Routine care helps reduce long-term wear, prevents premature failure of internal parts, and ensures stable power output. From a practical perspective, regular maintenance also lowers repair costs and minimizes downtime, especially for users who rely on their engraver for daily work.

Don’t stop here—browse related posts for even more valuable content!

Cleaning the Exterior Without Damaging Components

The first step in refreshing your pneumatic engraver is cleaning the exterior. Always disconnect the tool from the air supply before cleaning. Use a dry microfiber cloth to remove surface dust, followed by a slightly damp cloth for stubborn residue. Avoid using aggressive cleaning agents, as they may damage protective coatings or rubber grips.

Pay close attention to ventilation openings and connection points. Dust buildup in these areas can affect airflow and cooling. A soft brush or compressed air can help clear debris safely. Keeping the exterior clean not only improves appearance but also makes it easier to spot early signs of wear or damage.

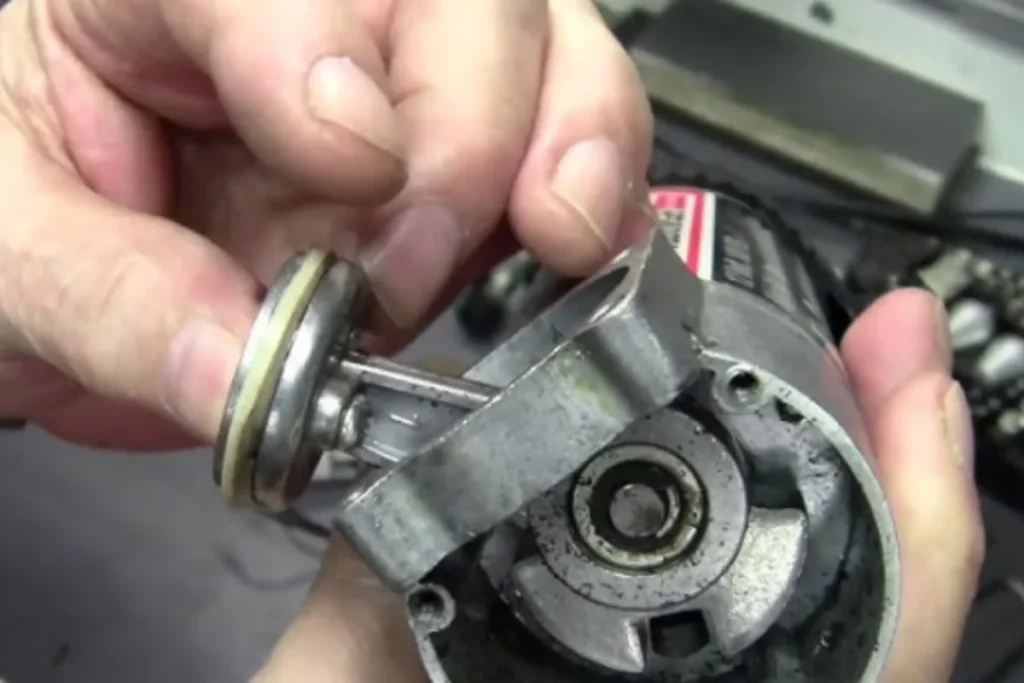

Caring for Internal Airflow and Moving Parts

Internal maintenance plays a major role in aging prevention. Over time, moisture and fine particles can accumulate inside a pneumatic engraver, affecting performance. Using clean, dry compressed air is essential. If your setup allows, install an air filter and moisture trap to protect the engraver from long-term internal corrosion.

Lubrication is another key factor. Apply a small amount of recommended pneumatic tool oil to the air inlet at regular intervals. This helps reduce friction between moving parts and ensures smoother operation. Proper lubrication can noticeably improve responsiveness and reduce vibration during engraving.

Managing Tool Aging and Wear Over Time

Tool aging is inevitable, but its effects can be controlled. Common signs of aging include inconsistent power, increased noise, or reduced precision. Addressing these issues early helps prevent further deterioration.

Inspect the engraver regularly for loose fittings, worn seals, or damaged hoses. Replacing small components before they fail completely is more cost-effective than repairing major internal damage. Keeping a simple maintenance log can help track usage hours and identify when routine checks or part replacements are needed.

Refreshing the Look Without Affecting Performance

A fresh appearance can improve both user experience and confidence in the tool. Some users choose to replace worn grips or protective sleeves to restore comfort and control. Others apply subtle cosmetic upgrades, such as protective wraps or custom labels, as long as airflow and heat dissipation are not restricted.

While cosmetic changes should never interfere with function, maintaining a clean and organized workspace also contributes to how the tool is perceived. A well-kept pneumatic engraver reflects professional habits and careful handling.

Storage and Daily Handling Practices

Proper storage significantly impacts the lifespan of a pneumatic engraver. When not in use, store the tool in a dry, dust-free environment. Avoid leaving it connected to the air supply when idle, as constant pressure can strain internal seals over time.

During daily use, handle the engraver with consistent grip pressure and avoid forcing the tool beyond its intended workload. Let the engraver do the work rather than applying excessive force, which increases internal wear and reduces accuracy.

Long-Term Benefits of Self-Maintenance

Taking responsibility for caring for your own pneumatic engraver offers several long-term advantages. First, it ensures consistent engraving quality, which is especially important for detailed or repetitive work. Second, it extends the usable life of the tool, reducing the need for frequent replacements.

Additionally, well-maintained tools retain higher resale value. For professionals or hobbyists who upgrade equipment periodically, this can make a noticeable difference. Most importantly, regular care builds familiarity with the tool, allowing users to recognize performance changes early and respond effectively.

Keeping Your Pneumatic Engraver at Its Best

Giving your pneumatic engraver a fresh new look is not about cosmetic perfection, but about maintaining reliability, efficiency, and control. Through regular cleaning, proper lubrication, careful aging management, and thoughtful storage, users can significantly extend the life of their engraver while restoring its original performance and appearance.

A well-maintained tool supports better craftsmanship and more predictable results. By investing a small amount of time in routine care, your pneumatic engraver can continue to perform with stability and precision long after its initial purchase.

There’s so much more to uncover—explore additional content that will intrigue you!