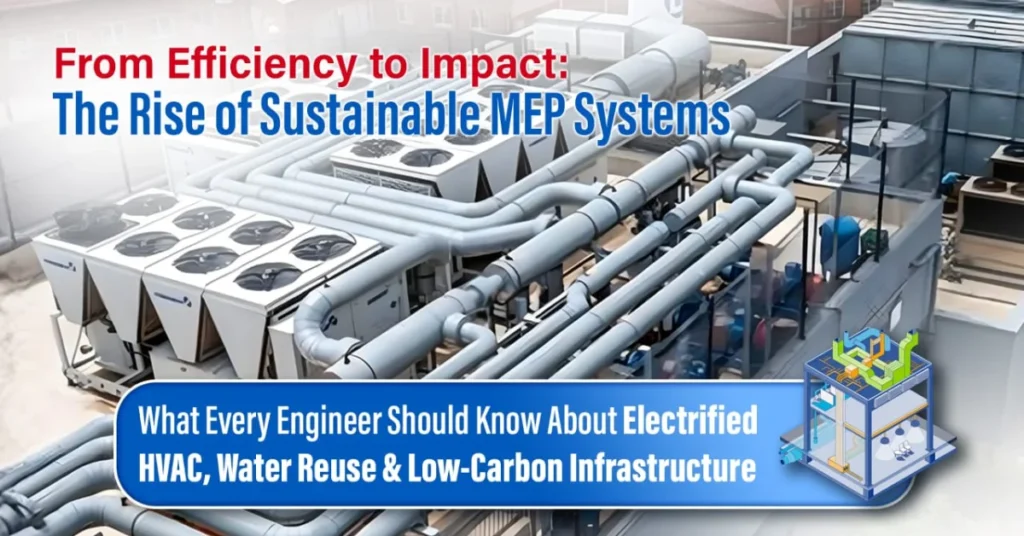

A quiet revolution is unraveling across the built environment. It’s reshaping the way Mechanical, Electrical, and Plumbing (MEP) systems are designed. What was once a niche conversation about efficiency has turned into a global mandate. This shift is driven by climate regulations, investor scrutiny, and rising expectations from building owners. Today, sustainability in MEP engineering services is as value-added as it is the defining metric of a modern building’s performance.

A Sector Under Pressure-Why Sustainability Now Sets the Agenda

From New York City’s Local Law 97 to the aggressive decarbonization targets in California’s Title 24, governments are sending a clear message: outdated building systems are no longer acceptable. Certification frameworks such as LEED, WELL, and Green Globes are elevating the standards for HVAC design and water efficiency. The result is an engineering environment where sustainability determines everything, from equipment selection to lifecycle planning.

Industry analysts suggest this transition represents one of the biggest engineering shifts in decades. Owners are demanding low-carbon building systems, electrified HVAC solutions, and real-time analytics that can deliver measurable reductions in energy and water consumption. And with the push toward net-zero buildings, MEP engineers are being asked to rethink their designs from the ground up.

To sum it up, the industry is moving from “build it efficiently” to “build it sustainably.” And that shift is fundamentally rewriting the rules of MEP engineering.

Codes Are Tightening, and Engineers Are Racing to Adapt

A wave of new regulations is rapidly reshaping sustainable MEP engineering standards, forcing design teams to rethink long-established practices. Updated editions of ASHRAE 90.1 and ASHRAE 189.1 now demand higher equipment efficiency, tighter HVAC controls, and better integration with building envelopes. The IECC adds deeper requirements for lighting controls, sub-metering, and energy-efficient electrical distribution.

At the local level, carbon-reduction laws, such as NYC Local Law 97, penalize buildings with high operational emissions, accelerating the shift away from fuel-based systems toward electrification. Certifications like LEED and WELL further push projects to adopt low-carbon materials, heat-recovery systems, and water-efficient plumbing.

These regulatory pressures mean MEP engineers can no longer treat codes as compliance checklists. Instead, they must design performance, carbon, and long-term sustainability in mind, often from the earliest schematic stages. The new rules are clear: efficiency is expected; sustainability is required.

The Great Electrification Push- Mechanical Systems Face a Rethink

Electrification is rapidly replacing gas-based systems in mechanical design, driven by carbon regulations and the shift toward low-emission buildings.

- Heat pumps, including air-source and geothermal, are becoming the preferred alternative to boilers due to higher efficiency and lower carbon impact.

- VRF (Variable Refrigerant Flow) systems are gaining mainstream adoption for flexible zoning and energy savings in commercial projects.

- Electrification requires revised HVAC load calculations, as electric systems behave differently across climate zones and seasonal temperature swings.

- Mechanical engineers must plan for higher electrical demand, coordinating closely with electrical design teams as electrified systems shift peak loads.

- Sustainable HVAC design now includes integration with renewable energy, battery storage, and smart building controls.

- Electrification is not just equipment replacement, it’s a full redesign of mechanical system architecture in response to ASHRAE and IECC performance standards.

These shifts highlight the growing importance of Building Engineering in HVAC system design, especially as engineers transition toward fully electrified, low-carbon mechanical solutions.

Smart Energy Management Transforming Electrical Engineering

Sustainability is redefining electrical system design, pushing engineers toward smarter, data-driven power distribution. Modern buildings require integration of renewable energy systems such as solar PV and Battery Energy Storage Systems (BESS) to support peak shaving, load shifting, and resilience.

- EV charging infrastructure is now a core design requirement, impacting feeder sizing, transformer capacity, and overall load diversification.

- Advanced smart meters and sub-metering systems enable granular tracking of electrical consumption, supporting energy reporting and carbon compliance.

- Demand response capabilities and automated load controls are becoming standard to manage peak demand and utility interaction.

- Low-voltage intelligent building systems (IBS), including networked lighting, IoT sensors, and automated controls, optimize energy performance across MEP systems.

- Electrical engineers must design real-time monitoring, power quality management, and grid-interactive technologies to support high-performance sustainable buildings.

Water Efficiency and Conservation Shaping Plumbing Design

Green building mandates are driving water-efficient plumbing design, prioritizing reduced potable water use and optimized system performance. Low-flow fixtures compliant with EPA WaterSense standards are now baseline requirements for commercial and residential projects.

- Greywater and blackwater reuse systems enable internal recycling for toilet flushing, irrigation, and cooling tower makeup, requiring advanced filtration and dual plumbing networks.

- Rainwater harvesting systems, including collection surfaces, storage tanks, and first-flush diverters, are increasingly integrated into non-potable water supply strategies.

- Engineers are optimizing hot-water recirculation loops with smart pumps and right-sized piping to minimize heat loss and reduce both water and energy waste.

- Plumbing material selection emphasizes low-embodied-carbon options, with growing preference for PEX, high-efficiency fixtures, and insulated piping systems.

- Compliance with LEED, WELL, and local water conservation codes pushes projects to adopt water reuse, sub-metering, and efficient distribution layouts.

Digital Engineering and Building Information Modeling as Enablers of Sustainable MEP Systems

Digital engineering is now at the center of sustainable MEP design and coordination, transforming the way engineers model, coordinate, and optimize building systems. With stricter energy codes and carbon-reduction targets, BIM provides the data-rich environment needed to analyze performance early, prevent costly field issues, and evaluate long-term environmental impact. Tools like Revit, Navisworks, IES, and digital twins have become indispensable for integrating sustainability into every phase of the MEP engineering process.

Key Technical Drivers

- Energy modeling (IES VE, Revit Insight, TRACE) helps engineers test HVAC, electrical, and plumbing performance before systems are built.

- Clash detection in Navisworks reduces rework, material waste, and carbon-intensive field changes.

- Digital twins enable real-time monitoring of building performance, energy usage, and equipment health.

- 4D/5D BIM workflows support lifecycle cost analysis and embodied carbon forecasting for long-term sustainability planning.

- Prefabrication and modular MEP assemblies reduce onsite waste, improve installation efficiency, and standardize high-performance system delivery.

- Early digital coordination ensures sustainability strategies are integrated from conceptual design, avoiding last-minute redesigns.

Low-Carbon Materials and the Rise of Environmental Product Transparency

Sustainability is now pushing MEP engineers to consider not just operational efficiency but the embodied carbon of every system and material they specify. This shift has made Environmental Product Declarations (EPDs), low-GWP refrigerants, and transparent material data essential in mechanical, electrical, and plumbing design. Engineers are moving toward PEX over copper, low-carbon insulation, and ASHRAE-approved refrigerants to meet global climate policies and certification requirements. As a result, material selection has become a strategic sustainability decision, directly influencing a building’s overall carbon footprint.

Integrating Renewables and High-Performance Technologies in MEP

As sustainability targets tighten, MEP systems are increasingly built around high-performance technologies that reduce operational carbon and support long-term efficiency. Modern buildings now rely on integrated renewable energy systems and advanced mechanical-electrical solutions that enhance resilience, optimize loads, and meet net-zero design expectations.

Key High-Performance MEP Technologies

- Geothermal heat pump systems for ultra-efficient heating and cooling

- VRF (Variable Refrigerant Flow) systems enabling zoned, low-energy mechanical control

- ERV/HRV energy recovery units to recycle heat and improve ventilation efficiency

- Solar photovoltaic (PV) systems for on-site renewable generation

- Microgrids to support independent operation and enhanced resilience

- Battery Energy Storage Systems (BESS) for peak shaving and load management

- Smart building controls for real-time optimization across HVAC and electrical systems

The Future of MEP Engineering in a Sustainability-Driven World

Sustainability has moved from a design aspiration to the defining force reshaping modern MEP engineering. As buildings shift toward net-zero energy, net-zero carbon, and climate-resilient performance, engineers must rethink how mechanical, electrical, and plumbing systems are conceived, integrated, and optimized. Electrification, renewable integration, advanced controls, water reuse, and healthier indoor environments are no longer optional, they are the new baseline.

MEP systems must now support all-electric operations, renewable generation, microgrids, heat recovery, and high-efficiency ventilation, while plumbing designs focus on conservation and reuse. Across every discipline, engineers are expected to deliver low-carbon, high-performance systems that remain resilient under climate stress and adaptable to future energy demands.

In this sustainability-first era, success belongs to the firms that embrace digital tools, transparent materials, and forward-looking engineering strategies. For the AEC industry, the message is clear: the future of MEP design is efficient, electrified, data-driven, and deeply committed to environmental performance, and those who adapt will lead the next generation of built environments.

Explore more insights crafted to spark new ideas and guide your next smart move.