Optical sorting machines have changed food processing by delivering higher product quality, stronger safety standards, and greater efficiency. AI in these systems boosts accuracy, increases yield rates, and improves quality. Automation now covers 55% of food and beverage manufacturing globally, with over 60% of farms expected to adopt these technologies by 2025.

Optical sorting machines have changed food processing by delivering higher product quality, stronger safety standards, and greater efficiency. AI in these systems boosts accuracy, increases yield rates, and improves quality. Automation now covers 55% of food and beverage manufacturing globally, with over 60% of farms expected to adopt these technologies by 2025. The table below illustrates the key impacts optical sorting machine technology brings to food processing:

| Impact Area | Description |

| Product Quality | AI increases accuracy and yield, enhancing product quality. |

| Safety | Growing consumer demand for contaminant-free foods drives improved safety measures. |

| Efficiency | Automation lowers labor costs and streamlines operations in food processing plants. |

| Cost-effectiveness | Predictive maintenance with AI reduces downtime and operational expenses. |

What Is an Optical Sorting Machine?

Optical sorting machines play a vital role in modern food processing. These machines use advanced technology to inspect and separate products based on visual characteristics. Companies rely on optical sorting machines to improve quality, safety, and efficiency in their operations.

How Optical Sorting Machines Work

An optical sorting machine uses cameras, sensors, and AI to scan food items as they move along a conveyor belt. The system detects differences in color, shape, size, and texture. When the machine identifies a defective or foreign item, it activates a rejection system, such as an air jet or mechanical arm, to remove the item from the production line. This process helps prevent contamination and spoilage, protecting both consumers and brand reputation.

Tip: Optical sorting machines automate the sorting process, reducing manual labor and increasing accuracy.

The main stages in the operation of optical sorting machines include:

- Feeding: Raw food enters the machine through a conveyor or feeder.

- Inspection: Cameras and sensors scan each item for specific attributes.

- Analysis: AI processes the data and identifies defects or foreign materials.

- Separation: The system removes non-conforming items using air jets or mechanical arms.

- Collection: Sorted products move on for packaging or further processing.

The table below shows the core components and stages of an optical sorting machine:

| Component/Stage | Description |

| High-Resolution Cameras | Capture detailed images and data, detecting variations in color, texture, shape, and size. |

| AI and Machine Learning | Process data to improve sorting accuracy, recognizing patterns and predicting defects. |

| Rejection Systems | Mechanisms that remove defective items from the production line. |

| Infeed | Products are introduced into the machine using conveyor belts or feeders. |

| Inspection | High-speed cameras analyze materials for characteristics like color and surface texture. |

Key Technologies in Optical Sorters

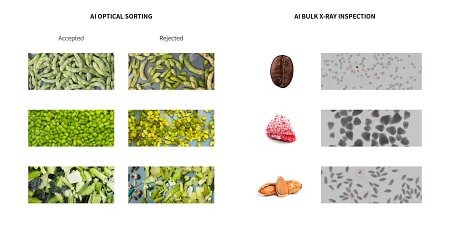

Optical sorters use several advanced technologies to achieve high accuracy and efficiency. Camera-based sorters detect color and shape, while laser-based systems measure dimensions and surface defects. Hyperspectral cameras capture hundreds of wavelengths, allowing for detailed material discrimination. AI-powered optical sorters learn and adapt to material variations, making real-time decisions and improving purity levels.

| Technology Type | Function |

| Camera-based Sorters | Versatile and cost-effective for color and shape detection; evolved to multi-spectral imaging. |

| Laser-based Sorters | Provides precision for dimensional measurements and surface defect detection; uses NIR for material identification. |

| Hyperspectral Cameras | Captures spectral signatures across hundreds of wavelengths for detailed material discrimination. |

- Optical sorters analyze thousands of characteristics at once.

- AI systems differentiate between similar-looking materials, reducing contamination.

- Hyperspectral imaging separates materials with similar appearances but different compositions.

Optical sorting technology continues to advance, helping food processors achieve higher standards of quality and safety.

Benefits of Optical Sorting Machines

Product Quality

Optical sorting machines raise product quality in food processing. These machines use advanced cameras and AI to inspect every item. They detect color, shape, and surface defects with high accuracy. Optical sorters perform 360-degree inspections, which helps them find even minor flaws in fruits and vegetables. For example, an optical sorter can identify and remove defects in potatoes, oranges, mandarins, and lemons. This process ensures only high-quality products reach the market.

- Optical sorting machines use AI technology to sort food items with precision.

- They help maintain strict quality standards by removing defective products.

- Optical sorters improve yield rates by sending only the best items forward.

Food processors rely on sorting technology to meet customer expectations. High product quality leads to better brand reputation and increased consumer trust.

Food Safety

Food safety is a top priority in food processing. Optical sorting machines play a key role in keeping food safe. Automated sorting systems achieve accuracy rates above 95% when detecting contamination. This level of precision is higher than manual inspection, especially during long shifts. Optical sorters use multiple detection technologies to find foreign materials and contaminants.

- Automated sorting machines comply with HACCP standards, lowering contamination risks.

- FDA-approved materials allow for easy cleaning and sanitizing, which helps maintain hygiene.

- Easy-to-clean sorters are important for seafood and meat processing, where safety is critical.

Optical sorting machines help processors meet strict safety regulations. They protect consumers from harmful substances and support public health.

Efficiency and Cost Savings

Optical sorting machines increase efficiency and reduce costs in food processing operations. These machines sort large volumes quickly, which speeds up production. They use infrared sensors and vision inspection to sort products based on specific features. This technology improves accuracy and reduces product waste.

| Benefit | Description |

| Reduction in Labor Costs | Automated sorting systems decrease reliance on manual labor, leading to savings on wages and overhead costs. |

| Improvement in Sorting Accuracy | High precision sorting reduces product waste, lowering material expenses significantly. |

| Acceleration of Sorting Workflow | Automated machines process large volumes quickly, reducing downtime and improving production speed. |

Optical sorting machines minimize waste by separating overripe or damaged items. Processors often see a return on investment within one to three years because of reduced waste and better safety. These machines also support sustainability by lowering energy use and minimizing landfill waste.

Note: Optical sorting solutions help companies meet environmental goals by improving recycling efficiency and reducing food waste.

Optical sorters make food processing more efficient and cost-effective. They help companies stay competitive and meet industry standards.

Applications of Optical Sorting Machines

Sorting Fruits and Vegetables

Optical sorters play a vital role in sorting fruits and vegetables. These machines use advanced imaging and sensor technology to inspect each item as it moves along the line. They separate produce based on size, color, shape, and quality. This process ensures that only the best fruits and vegetables reach the market. Optical sorters assess quality in real time, which leads to higher efficiency and improved accuracy compared to manual sorting. Automation also reduces labor costs and meets the growing demand for food safety. In tomato processing, sorters separate ripe tomatoes from unripe or damaged ones, which helps create high-quality sauces. In apple packing, they detect rot and bruises, protecting brand reputation.

RaymanTech offers the AI Medium Speed Optical Sorter, which handles fragile and moisture-rich products like fresh vegetables and delicate fruits. Its multi-view imaging technology provides nearly 360° coverage, detecting even minor defects.

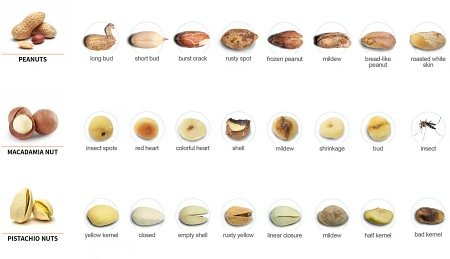

Grains, Nuts, and Seafood

Optical sorters deliver high precision when sorting grains, nuts, and seafood. They ensure products meet strict quality standards by identifying visual differences. These machines sort grains by removing discolored kernels and sort peanuts by eliminating shells and debris. For seafood, optical sorters detect and remove foreign materials, which is crucial for safety. The Belt Optical Sorter from RaymanTech works well with larger or irregularly shaped items, while the Chute Optical Sorter is ideal for small, free-flowing grains and nuts.

Key benefits include:

- Rapid sorting for increased production efficiency

- Consistent sizing and color sorting for uniform products

- Customizable settings for different product types

- Enhanced traceability through data collection

Removing Foreign Materials

Optical sorters use cameras and sensors to detect the color, shape, and size of materials. This technology allows for precise sorting and effective removal of foreign materials from food products. The RaymanTech Optical Sorting System uses AI and multi-view imaging to spot micro-defects and impurities, even in frozen seafood or meat. Its user-friendly design supports quick cleaning, which helps maintain hygiene compliance in food processing facilities.

| Feature Type | Description |

| AI and Machine Learning | Adaptive inspection that improves over time and reduces false rejects |

| 3D Vision Systems | Accurate height and volume measurements, detecting hidden defects |

| Multispectral Imaging | Reveals defects not visible to the human eye |

Optical sorters reduce food waste by efficiently removing defective items and contaminants, making them essential in modern food processing applications.

How to Choose the Right Optical Sorting Machine

Factors to Consider

Selecting the best optical sorter for food processing requires careful evaluation of several criteria. Companies should assess their product types, production volume, and facility environment. Advanced machines with AI and machine learning offer precise defect detection and improve operational efficiency. Compatibility matters because some sorters handle a wide range of materials, including vegetables and pharmaceuticals. Energy efficiency helps reduce costs while maintaining high performance. Scalability allows businesses to adapt to growth and increased demand. Reliable after-sales support ensures long-term machine performance.

| Criteria | Description |

| Technology | AI and machine learning for accurate defect detection. |

| Compatibility | Handles diverse materials, such as vegetables and grains. |

| Energy Efficiency | Low operational costs with strong performance. |

| Scalability | Adapts to business growth and higher production needs. |

| After-sales Support | Support services to maintain machine longevity and performance. |

Tip: Operators benefit from hands-on training and troubleshooting workshops. Access to 24/7 technical support helps resolve issues quickly.

Matching Machine Types to Products

Different food processing applications require specific optical sorting machines. Companies must match machine types to their products and processing environments. For example, the RaymanTech AI Medium Speed Optical Sorter works well with fragile and moisture-rich items, such as fresh vegetables. The Belt Optical Sorter suits larger or irregularly shaped products, while the Chute Optical Sorter is ideal for small, free-flowing grains and nuts.

| Industry | Application Description | Benefits |

| Food Processing | Removes defects from produce, like sorting vegetables. | Reduces waste by 20-30%, increases yield by 15%. |

| Recycling | Separates plastics by type and contamination. | Boosts accuracy, lowers labor costs. |

| Pharmaceuticals | Detects contaminants in powders. | Improves safety and purity. |

Training for operators includes hands-on experience with weight and vision sorters. Troubleshooting workshops build confidence and skill. Continuous technical support ensures smooth operation.

To choose the right optical sorting machine, companies should analyze their needs, consider product types, and review processing environments. RaymanTech offers models for various applications, helping businesses achieve high standards in food processing.

Optical sorting machines deliver many advantages in food processing. Companies see improved product quality, reduced labor costs, and increased throughput. These machines help processors comply with food safety regulations, enhance brand reputation, and support eco-friendly practices by reducing food waste and improving energy efficiency.

| Future Automation Trend | Impact on Food Processing |

| AI-powered sorting | Raises accuracy and quality control |

| Data-driven systems | Boost efficiency and reduce errors |

| Automated adjustments | Lower operational costs and save time |

Industry experts recommend advanced solutions like the RaymanTech Optical Sorting System. Automation and data-driven quality control will shape the future of food processing, making these technologies essential for success.

FAQ

How do cutting-edge optical sorters improve consistent product quality in the food processing industry?

Cutting-edge optical sorters use advanced vision systems to inspect processed food products. They detect defects and remove unwanted items. This technology helps companies deliver consistent product quality to customers.

What are the main applications in recycling for optical sorting machines?

Optical sorting machines play a key role in recycling. They separate plastics, metals recycling, and other materials. These machines also support applications in recycling for the pharmaceutical industry by removing contaminants.

Can optical sorters handle pharmaceuticals and processed food products?

Optical sorters work with pharmaceuticals and processed food products. They use sensors to detect impurities. The pharmaceutical industry relies on these machines to maintain safety and purity.

Why are advanced vision systems important for metals recycling and pharmaceuticals?

Advanced vision systems help identify small defects in metals recycling. They also ensure pharmaceuticals meet strict standards. These systems improve sorting accuracy and reduce errors.

How do optical sorters support the pharmaceutical industry and applications in recycling?

Optical sorters help the pharmaceutical industry by detecting contaminants. They also support applications in recycling by separating materials efficiently. Companies use these machines to improve safety and reduce waste.