If you’ve ever sat at a bar and admired a perfectly poured pint—cold, crisp, and with just the right amount of foam—you’re seeing the result of far more engineering than meets the eye. Behind every tap handle lies a network of lines, regulators, cooling systems or Draft Beer Cooling, and careful thermal calculations that ensure each beer tastes exactly as the brewer intended.

For bar owners, event venues, and even small breweries, draft system performance is not just about flavor—it’s about profitability. Every ounce of foam that spills into the drip tray is wasted revenue. Every pint served too warm risks a bad review. To avoid that, you need to understand one key concept: BTU, or British Thermal Units. This number determines how much cooling power your draft system really needs.

More knowledge. More inspiration. Click Related Posts to explore now!

Why Temperature Control Is Serious Business

In draft beer service, temperature equals consistency. Beer that’s even a few degrees too warm will foam excessively, losing carbonation and flavor. Each pour might look like a chemistry experiment instead of a satisfying pint.

For bar managers, that foam represents shrinkage—a product you paid for but can’t sell. Multiply that by dozens of pours each night, and the losses add up quickly.

That’s why temperature management is part of the operational DNA of successful bars and breweries. It’s not just a matter of customer comfort; it’s a key part of cost control and brand consistency.

Understanding BTU and Cooling Capacity

BTU, or British Thermal Unit, measures how much heat energy needs to be removed from a system. In the context of draft beer, BTUs represent the cooling power your system needs to keep the beer cold as it travels from the keg to the tap.

Several variables influence BTU requirements:

- The length of your beer lines (longer lines need more cooling).

- Ambient room temperature.

- Number of active taps.

- The insulation quality of your trunk lines and towers.

If your cooling system can’t remove enough heat, beer warms up before reaching the faucet—causing foam, wasted product, and flavor degradation. On the other hand, oversizing your system wastes electricity and increases costs unnecessarily.

Before you invest in any new cooling equipment, it’s smart to estimate your needs accurately. A Draft Beer BTU Calculator helps you determine the right cooling capacity based on your setup’s variables. This ensures your system runs efficiently, your beer pours perfectly, and your customers keep coming back.

Glycol Systems and Long-Draw Configurations

Most bars with short runs—where kegs sit directly under the bar—can rely on simple air-cooled systems. But once you move the kegs to a walk-in cooler or a remote storage area, things get more complex.

That’s where glycol power packs come in. These systems circulate a cold glycol-water mixture through insulated trunk lines alongside beer lines. The glycol absorbs heat and maintains a consistent temperature from keg to faucet, even across distances of 25–100 feet or more.

However, these systems must be sized correctly. Too little BTU power, and the beer warms halfway through the line. Too much, and the system overworks unnecessarily. Using the Draft Beer BTU Calculator before installation helps ensure your chiller matches your real-world cooling needs.

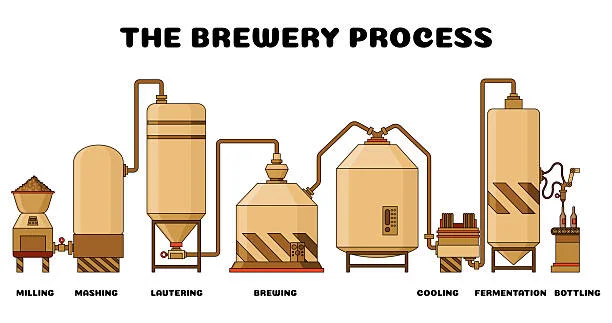

The Components That Keep Draft Systems Running

A high-quality pour depends on more than cooling power. Each component in your draft system plays a role in maintaining stability and sanitation. These are often referred to as draft system parts—the physical hardware that connects, regulates, and delivers beer.

Here’s what they include:

- Taps and faucets: The final control point for beer flow and foam management.

- Shanks and towers: The thermal bridge between the cooling system and the tap—critical to keep cold.

- Trunk lines: Multi-line bundles carrying both beer and glycol coolant. Proper insulation here is essential.

- Regulators and gas tanks: Maintain consistent CO₂ or nitrogen pressure to preserve carbonation.

- Couplers: Connect the keg to the beer line and ensure a tight, sanitary seal.

- Drip trays and cleaning hardware: Often overlooked but vital for hygiene and maintenance.

If even one of these parts fails—say, a pressure leak in the regulator or a warm tower—you’ll see it instantly in your pour quality. That’s why system audits, temperature checks, and preventive maintenance should be routine, not reactive.

Maintenance Equals Money Saved

Neglecting your draft system doesn’t just risk bad beer—it directly impacts profit margins. Regular cleaning prevents bacterial growth and off-flavors, while maintaining proper cooling ensures consistent carbonation and serving temperatures.

Smart bar owners implement maintenance schedules that include:

- Weekly line cleaning using approved solutions.

- Temperature and pressure checks during opening and closing.

- Inspection of all draft system parts for wear and tear.

- Monthly review of glycol temperature and flow settings.

This attention to detail protects your equipment, reduces downtime, and guarantees guests experience your beer exactly as intended.

The Future of Draft Service

The world of draft beer is evolving fast. Portable keg systems, mobile event bars, and seasonal pop-ups are becoming standard for breweries and caterers alike. Many of these rely on compact glycol chillers or even ice-based jockey boxes for outdoor events.

In every case, the same fundamentals apply: control the temperature, manage your pressure, and understand your BTU requirements before you pour. Technology is making it easier than ever to monitor draft systems remotely, but the core principles—good design, proper sizing, and proactive maintenance—never change.

Final Thoughts

Behind every great pint of beer lies a balance of physics, engineering, and precision. Whether you’re running a high-volume pub or a small event setup, the science of draft cooling directly affects your bottom line.

Understanding BTUs and your draft system parts isn’t just about technical curiosity—it’s about delivering a consistent customer experience and protecting your profits. Use the Draft Beer BTU Calculator to size your system correctly, maintain your equipment regularly, and treat every pour like it’s the first impression of your brand.

Because in the business of beer, cold isn’t just refreshing—it’s revenue.

The best reads are one click away—Explore More for endless discovery!