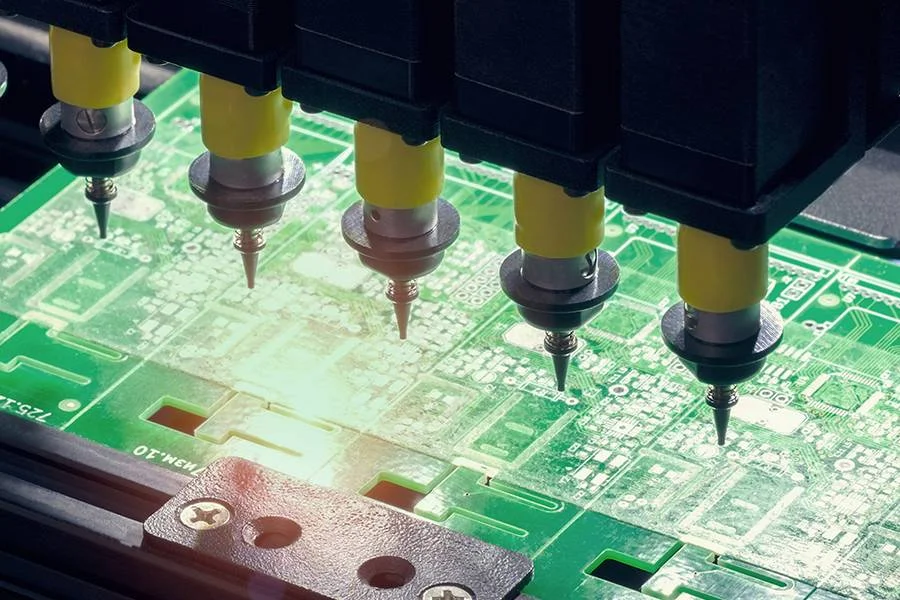

Finding the right manufacturing partner is a critical step for any electronics project. You need components that are both reliable and fit within your budget. This is especially true when it comes to printed circuit boards (PCBs), the foundation of modern electronic devices. Navigating the world of custom PCB fabrication and PCBA solutions can seem complex, but it doesn’t have to break the bank. It is possible to get high-quality, affordable boards when you know what to look for and who to partner with.

This guide will explore how to secure affordable custom PCB fabrication without sacrificing the expert quality control that ensures your project’s success. We will cover the key factors that influence cost, the importance of a robust quality assurance process, and the benefits of choosing a manufacturing partner dedicated to both excellence and value.

Understanding the Balance: Cost vs. Quality

In electronics manufacturing, the idea that high quality always comes with a high price tag is a common misconception. While cutting corners can lead to cheaper initial costs, it often results in product failures, costly redesigns, and a damaged reputation. The real goal is to find value, which is the perfect intersection of affordability and reliability.

A smart fabrication partner optimizes its processes to reduce waste and improve efficiency. These savings are then passed on to you, the customer. They achieve this balance by investing in modern technology, streamlining their workflow, and leveraging economies of scale. This approach ensures you receive a dependable product at a competitive price point.

Key Factors Influencing PCB Fabrication Costs

Several variables determine the final cost of your custom PCBs. Understanding them can help you make informed decisions to optimize your design for affordability.

- Board Material: The substrate material is a primary cost driver. Standard FR-4 is the most common and cost-effective option for a wide range of applications. High-frequency or high-temperature materials like Rogers or polyimide are more specialized and therefore more expensive.

- Board Size and Complexity: Larger boards naturally require more material and production time. Similarly, complex designs with many layers, fine traces, and tight tolerances demand more precision and advanced equipment, increasing the cost.

- Number of Layers: A simple single-sided or double-sided PCB is much cheaper to produce than a multi-layer board. Each additional layer adds complexity to the lamination and drilling processes, which raises the price.

- Order Quantity: Volume plays a significant role. Small prototype runs have a higher per-unit cost due to setup fees. Larger production runs allow manufacturers to spread these initial costs across more units, significantly lowering the price per board.

By considering these factors during the design phase, you can often make small adjustments that lead to significant cost savings without compromising the board’s function.

The Critical Role of Expert Quality Control

Affordability is meaningless if the final product doesn’t work. This is why expert quality control (QC) is non-negotiable. A thorough QC process catches defects early, prevents faulty products from reaching the end-user, and guarantees that every board meets your exact specifications.

A reliable PCB manufacturer integrates quality checks throughout the entire fabrication process, from initial design review to final inspection. This commitment to quality ensures consistency and performance.

Essential Quality Control Checkpoints

A comprehensive quality assurance system includes several key inspection stages. These checks are designed to verify the integrity of the PCB at every step.

- Design for Manufacturability (DFM) Check: Before production even begins, a DFM check analyzes your design files for potential issues that could cause problems during fabrication. This proactive step helps catch errors, optimize the design for efficiency, and prevent costly delays.

- Automated Optical Inspection (AOI): AOI systems use cameras to scan each board and compare it to the original design file. This automated process is incredibly effective at detecting manufacturing defects such as incorrect trace widths, spacing issues, short circuits, or open circuits.

- X-ray Inspection: For multi-layer boards or those with complex components like Ball Grid Arrays (BGAs), X-ray inspection is essential. It allows technicians to see through the layers and inspect solder joints, connections, and internal alignments that are not visible on the surface.

- Electrical Testing (E-Test): The final step is often an electrical test, where each board is tested for continuity and isolation. This “flying probe” or “bed of nails” test confirms that all electrical pathways are correct and that there are no shorts or opens.

Choosing the Right Fabrication Partner

The benefits of working with a manufacturer that prioritizes both affordability and quality are clear. You get a reliable product that fits your budget, allowing you to bring your project to market successfully. Such a partner acts as an extension of your team, providing guidance and support throughout the process.

When selecting a partner, look for transparency in their pricing, a clear explanation of their quality control procedures, and a willingness to work with you to optimize your design. A good manufacturer is invested in your success, knowing that it leads to a long-term, mutually beneficial relationship. This partnership allows you to focus on innovation, confident that the backbone of your electronics is in expert hands.