Some operations can tolerate occasional failures. Others can’t. Water treatment plants, hospital infrastructure, mining ventilation systems, and food cold chains all fall into that critical category where control system failure creates immediate safety risks or economic disasters. That’s where trusted industrial controls in Australia become absolutely essential rather than just preferable. These applications require more than good equipment—they need proven systems with established track records, local support networks, and compliance with Australian standards that aren’t optional. The consequences of getting it wrong go beyond money or inconvenience into territory where people’s safety or essential services are at stake.

Safety Integrity Levels and Certification Requirements

Critical applications often require SIL-rated equipment—Safety Integrity Level ratings that quantify how reliably a safety function prevents hazardous failures. SIL 1 represents the lowest integrity level, SIL 4 the highest. A SIL 2 system, common in many industrial applications, must maintain safe operation with a probability of dangerous failure between 0.01 and 0.001 per year.

Getting SIL certification isn’t just about testing individual components. It requires analyzing the entire safety loop—sensors, logic solvers, and final control elements together. Australian facilities operating under major hazard facility regulations or specific industry standards often need documented SIL analysis for critical safety functions. This isn’t paperwork for its own sake—it’s systematic proof that your safety systems will actually work when needed.

Expand your knowledge with this related post designed to fuel your curiosity.

Local Support Infrastructure Matters Critically

International brands might offer excellent products, but if the nearest service center is in Singapore and replacement parts take two weeks to arrive, that creates vulnerability. Critical applications need local support—technicians who can be on-site within hours, not days. Parts inventory located in Australia, not overseas warehouses. Technical support that operates in Australian time zones and understands local regulations and standards.

This requirement has driven growth in local control system integrators and equipment suppliers who maintain Australian inventory and service networks. The premium paid for local support becomes trivial compared to the cost of extended downtime waiting for overseas parts or remote troubleshooting across time zones. Some operations maintain their own spare parts inventory for critical components, essentially self-insuring against supply chain delays.

Harsh Australian Environments Challenge Equipment

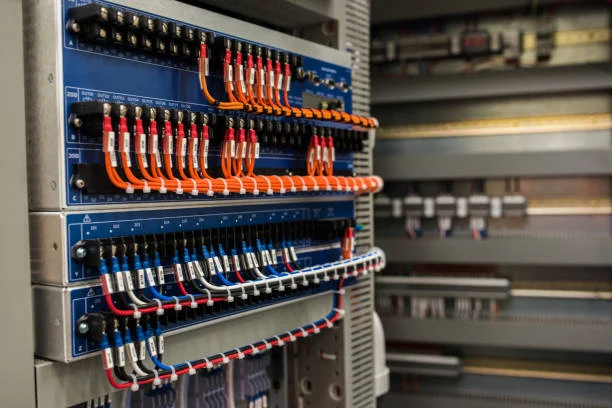

Australian conditions test equipment limits. Summer temperatures in Darwin or inland mining sites regularly exceed 40°C. Coastal facilities deal with salt-laden air that corrodes electronics. Remote locations experience power quality issues—voltage fluctuations, frequency variations, and transient spikes that more stable grids filter out. Dust storms, cyclones, and occasional floods add physical challenges.

Control equipment for critical Australian applications needs design margins that account for these conditions. Heat-rated components, conformal coating on circuit boards, sealed enclosures, and surge protection aren’t optional extras—they’re necessary for reliable long-term operation. Equipment that works fine in European climate-controlled facilities might struggle in Australian conditions without proper specification.

Compliance with Australian Standards and Regulations

AS/NZS 61439 for low-voltage switchgear, AS/NZS 3000 for electrical installations, relevant Australian standards for machinery safety—critical applications need documented compliance. This goes beyond having the right stickers on equipment. It means installation practices match Australian requirements, documentation meets local standards, and testing procedures follow prescribed methods.

Workplace health and safety regulations make facility operators responsible for ensuring equipment safety. Using non-compliant equipment or installation practices creates liability exposure that’s particularly risky for critical applications where failures might cause injuries. Many insurance policies include requirements for standards compliance, making this a financial issue beyond the regulatory one.

Cybersecurity for Connected Control Systems

Critical infrastructure increasingly faces cybersecurity threats, and control systems represent vulnerable targets. Unlike IT systems that get regular security updates, industrial control systems often run for years without patches, creating persistent vulnerabilities. Australian facilities in critical sectors face specific guidelines around cybersecurity, including the Security of Critical Infrastructure Act requirements for certain operations.

Trusted control systems for critical applications need security built in from design—not added as an afterthought. Network segmentation isolates control systems from business networks. Authentication prevents unauthorized access. Audit logging tracks all system changes. These measures don’t eliminate risk entirely, but they substantially reduce vulnerability to common attack vectors.

Discover hidden gems when you explore more of what we’ve thoughtfully curated.