Water safety can’t be compromised in commercial operations. A commercial uv water treatment system range provides chemical-free disinfection that eliminates bacteria, viruses, and parasites without affecting water taste or creating harmful byproducts. These systems handle flow rates from small restaurants using 10 gallons per minute to industrial facilities processing thousands of gallons per minute. The EPA recognizes UV treatment as an effective barrier against Cryptosporidium and Giardia—parasites that resist chlorine—making it increasingly common in municipal water systems, beverage production, and food processing plants where water purity directly impacts product safety and consumer health.

The Technology Behind Water Disinfection

UV treatment for water differs from air disinfection because of transmission challenges. Water absorbs UV-C, especially if it contains dissolved organics or minerals. Transmittance matters hugely—high-quality source water might transmit 95% of UV at 254nm, while water with tannins or iron might transmit only 75%. Commercial systems account for this with higher lamp outputs and longer exposure chambers.

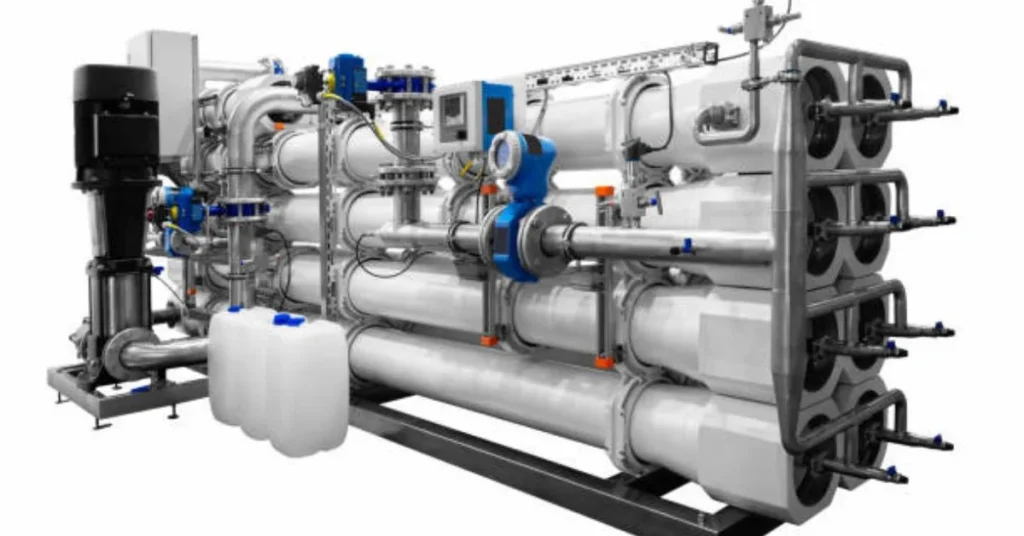

Flow-through reactor design determines contact time. Water enters a chamber housing one or multiple UV lamps, flows around them, and exits. The chamber geometry ensures turbulent flow so all water molecules spend adequate time in the UV field. Laminar flow would let water near the chamber walls slip past with minimal exposure.

Dosage requirements vary by target organism. Standard bacterial disinfection needs about 10 mJ/cm², while Cryptosporidium requires 40+ mJ/cm² for effective inactivation. Commercial systems typically deliver 30-50 mJ/cm² to provide a safety margin. This higher dosage ensures effectiveness even if water quality fluctuates or lamps degrade slightly between maintenance cycles.

Dive into our related post—crafted to give you more clarity and fresh insight.

System Sizing and Selection

Flow rate is the primary specification. A small café needing point-of-use treatment might require 5-10 GPM capacity, while a bottling plant could need 500+ GPM. Undersizing creates bottlenecks during peak demand—the system limits flow to maintain proper contact time, which backs up operations.

Water quality analysis is critical before selecting equipment. Testing for UV transmittance (UVT), total suspended solids, hardness, and iron content tells you what pre-treatment might be necessary. Water with UVT below 75% needs filtration or other treatment first. High hardness causes scaling on quartz sleeves that house the UV lamps, blocking light transmission.

Medium-pressure versus low-pressure lamps suit different applications. Low-pressure lamps are more energy-efficient (about 35-40% UV output efficiency) and work well for consistent disinfection. Medium-pressure lamps emit broader spectrum UV and excel at destroying chemical contaminants through advanced oxidation, though they use more power. Most commercial water treatment uses low-pressure for straight disinfection.

Pre-Treatment Integration

Sediment filtration should precede UV systems. Particles create shadows that shield microorganisms from UV exposure. Commercial installations typically use 5-10 micron cartridge filters or automatic backwashing media filters. The tighter the filtration, the better the UV performance.

Water softening matters in hard water areas. Scale buildup on quartz sleeves happens gradually but severely impacts performance. Some facilities install small ion exchange softeners specifically for UV system feed water, while others use polyphosphate injection to keep minerals in suspension.

Iron removal is non-negotiable when levels exceed 0.3 ppm. Dissolved iron oxidizes on quartz sleeves, creating an opaque coating that blocks UV. Oxidation-filtration systems remove iron before water reaches the UV unit. Trying to skip this step leads to weekly sleeve cleaning instead of quarterly, which defeats the low-maintenance advantage of UV systems.

Monitoring and Control Systems

UV intensity sensors provide real-time performance data. These photodetectors measure actual UV output reaching the water, not just lamp power consumption. If output drops below the setpoint (indicating lamp degradation or fouling), alarms trigger and some systems automatically divert flow to a holding tank or alternate treatment.

Flow monitoring ensures proper dosage. Commercial controllers calculate actual dosage based on current flow rate and measured UV intensity. If flow suddenly increases beyond system capacity, controls can either restrict flow or sound alarms. This prevents undertreated water from entering the distribution system.

Lamp hour meters track when replacement is due. Most commercial UV lamps last 9,000-12,000 hours of operation. Running lamps beyond rated life is risky—output may have dropped 30-40% even though the lamp still glows. Facilities with critical operations keep spare lamps on-site for immediate replacement.

Maintenance Realities

Quartz sleeve cleaning frequency depends on water quality. Clean municipal water might need cleaning every 6-12 months. Well water with minerals could need monthly attention for Commercial UV water treatment system. The cleaning process involves removing sleeves from the chamber, soaking in citric acid solution to dissolve scale, and inspecting for cracks or cloudiness that indicates replacement is needed.

Lamp replacement should happen on schedule, not on failure. Commercial operations can’t afford downtime, so proactive replacement during planned maintenance prevents unexpected shutdowns. Some facilities stagger lamp replacement in multi-lamp systems to spread costs and reduce the chance of simultaneous failures.

System validation after any maintenance verifies performance. This involves challenge testing—either using biological indicators or measuring bacterial counts pre and post UV treatment. Some jurisdictions require third-party validation for facilities providing public drinking water or producing bottled beverages.

Energy and Operating Costs

Power consumption varies by system size. A 20 GPM commercial unit might draw 200-300 watts continuously, while a 500 GPM system could need 5-10 kilowatts. This is still far less than heating water for thermal pasteurization or the chemical/neutralization costs of chlorination systems.

Operating costs beyond electricity are minimal. Annual expenses typically include replacement lamps ($200-500 per lamp depending on size), cleaning supplies ($50-100), and periodic testing ($200-300). This compares very favorably to chemical treatment systems that need continuous consumable purchases.

Explore more content and unlock paths that lead to better ideas and solutions.