Many people tend to think that the automotive steering system is straightforward – you rotate the steering wheel, and the car turns. When driving and making those turns, it is all smooth and flawless, especially for the modern car.

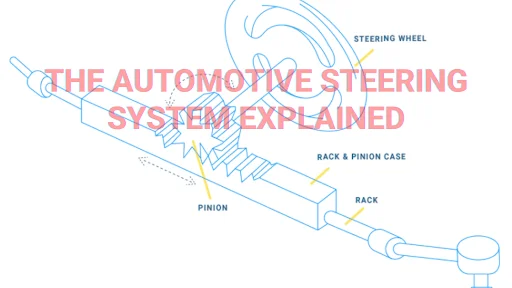

But what’s behind the smooth motion is a system comprising the steering column, intermediate shaft, pinion gear, rack, tie rods, and steering knuckles.

From the early 1900s, when manual steering with worm-and-sector or worm-and-roller gears first emerged, the automotive steering system has undergone a massive transformation to date. The advancements serve to enhance comfort and safety.

Because these improvements are so extensive, slight manufacturing errors, even for CNC-machined parts like shafts, can be easily apparent. Hence, it is worthwhile to understand the intricacies of this system. There is no better way to start than through this rundown of the components, functions, and machining processes of the steering system parts.

Discover more insights in this related post tailored just for you.

What Is An Automotive Steering System?

The automotive steering system is an arrangement of shafts and other components that convert the rotation of the steering wheel into angular changes in the wheels of a car.

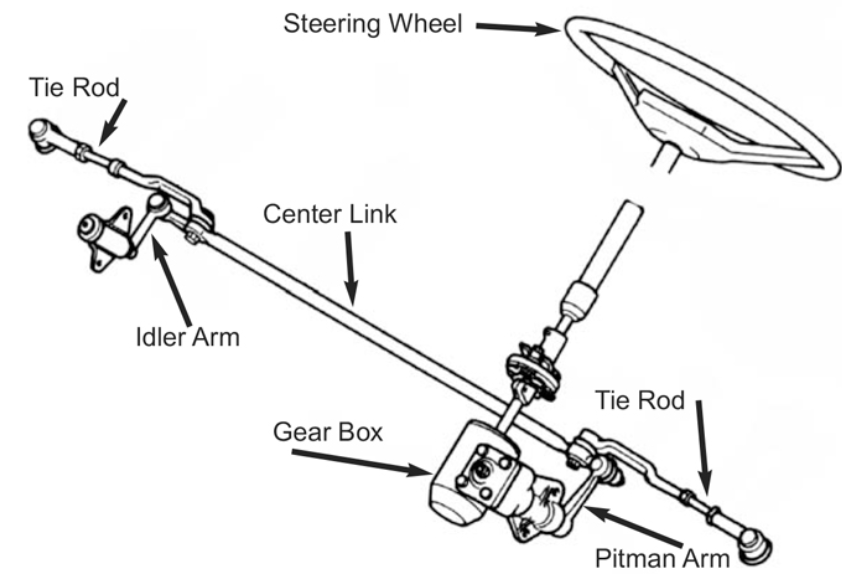

With parts like the steering column, rack, tie rods, center link, and idler arms, this system also ensures that the driver’s hands on the steering wheel are free from vibrations and shocks transmitted to the car via the wheels.

For the power steering system, there are additional components, including a coupler, damper, and pump.

How Does Car Steering Work?

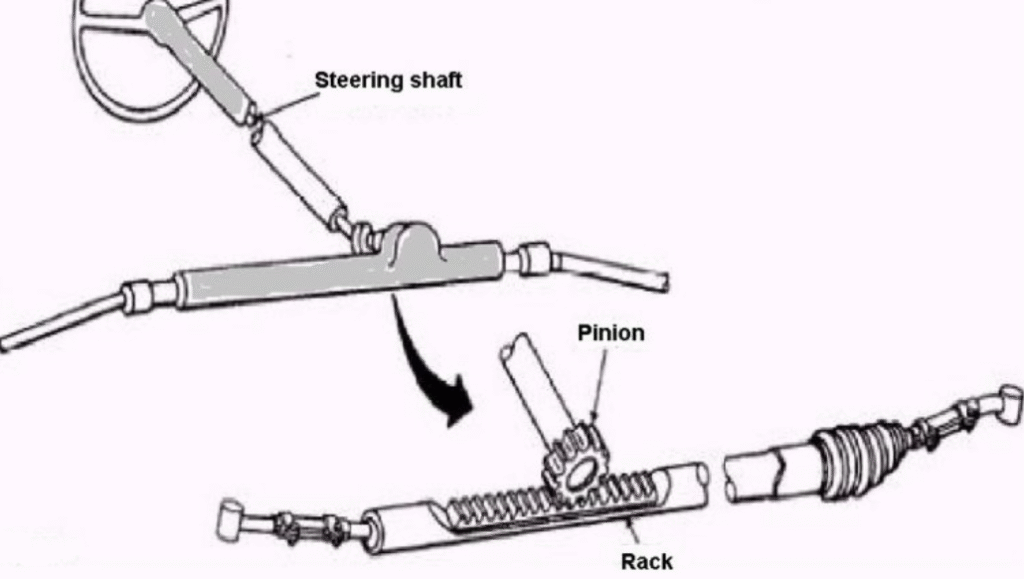

The working mechanism of the car steering entails a shaft connected to the steering wheel that rotates when the driver rotates the wheel. The shaft rotates a pinion on a rack. The rack, moving linearly, moves the tie rod, which in turn rotates the car wheel.

The level of turning or angle on the wheels on the road depends on the size of the pinion. A large pinion translates to a large turn, and vice versa.

Types Of Automotive Steering Systems

Three types of automotive steering systems exist: Rack & pinion, recirculating ball, and worm & sector.

Rack & Pinion

Rack And Pinion Steering System

This system gets its name from its gearset of a rack and pinion, which is in a metal tube. Each end of the rack connects to a tie rod, a special metal rod that joins the steering knuckle to the rack. Most of the SUVs and small cars today have this automotive steering system.

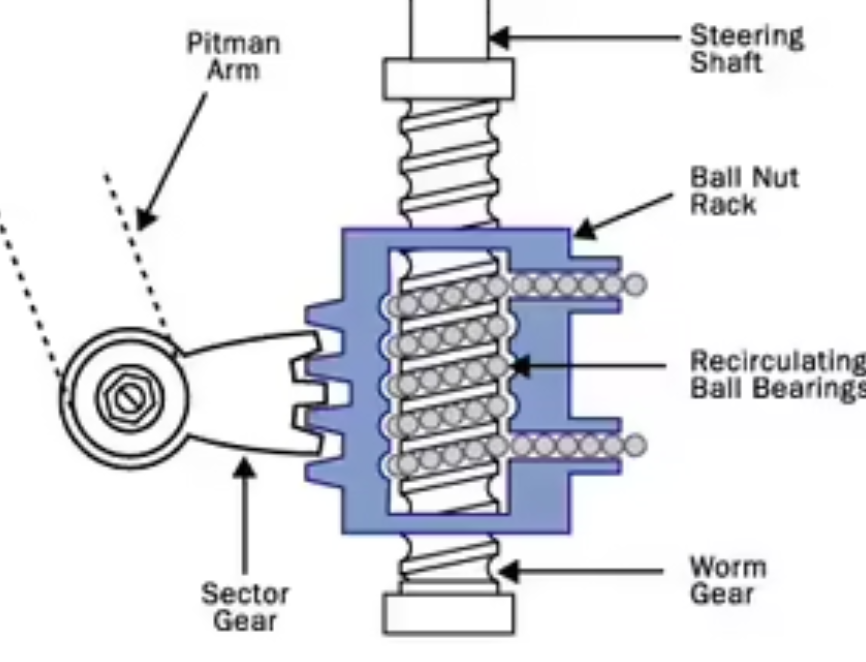

Recirculating Ball

Recirculating ball automotive steering system

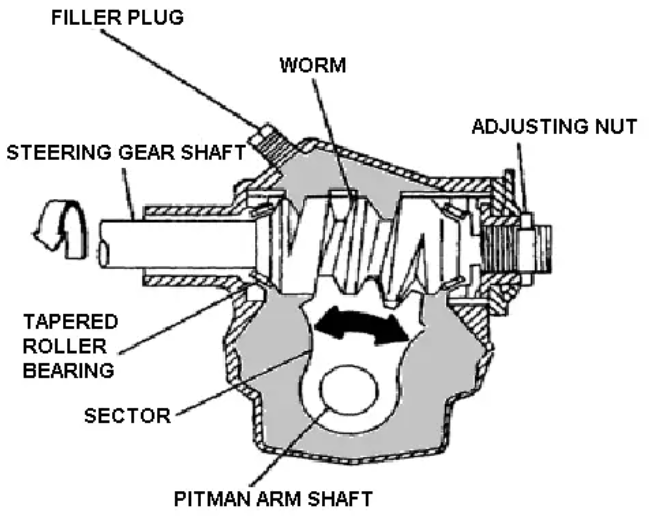

Worm & Sector Steering System

The worm & sector steering system of a car works through the meshing of a worm gear and a sector gear. A sector gear looks like a piece of a pie with teeth along the arc.

Worm and sector steering system

How Do Tie Rods Work?

Tie rods connect the steering knuckle to the steering rack. These rods jump into action every time the steering wheel is turned. These components ensure the wheel turns as expected by turning the rotation of the steering wheel into a push or pull on the wheels. The force of the steering wheel reaches the tie rods through the steering rack.

Tie rods and other parts

Essentially, a tie rod has an outer and inner segment. The outer segment connects to the steering knuckle, while the inner one is linked to the center link or steering rack. An adjustable sleeve in between is instrumental in fixing wheel alignment angles.

The tie rod should be strong but also weight–sensitive, hence the preference for high-strength steel by most manufacturers.

What Is Cold Steering?

Cold steering is a common problem that occurs in automotive steering systems during cold weather. Signs of cold steering are hissing or squeaking sounds, heaviness on the steering wheel, vibration of the steering wheel, or even non-responsiveness from all steering controls.

A few checks can fix cold steering, including for the rack & pinion, power steering hoses and pump, and power steering fluid level.

Manufacturing Processes for Automotive Steering Systems

The different components that comprise the auto steering system are manufactured through several processes, including injection molding, metal casting, and CNC machining. 3D printing is largely used in the rapid prototyping stages.

Injection Molding

The automotive steering wheel system parts that require top accuracy and precision can be made through injection molding. A perfect example of parts is the steering wheel cover. In injection molding, a mold designed in the shape of the desired part is fed with molten material. This material is ready for use when it cools and the mold is removed.

This technique is reliably used by manufacturers to manufacture car dashboard parts.

An injection-molded steering column cover

2. Metal Casting

This is another prominent manufacturing method, which is characterized by processes such as the traditional sand casting, the precise investment casting, and the more advanced and modern High-Pressure Die Casting (HPDC). Most manufacturers of automotive steering systems use this technique, particularly for aluminum parts like brackets and housings.

CNC Machining

CNC machining is an effective method for producing shafts and other relevant parts of the automotive steering system. Whether it is turning, milling, drilling, or gear machining, the relevance of this solution in producing the system’s parts is vast.

3D Printing

3D printing is mostly for prototyping purposes, which is important in the design stage. The manufacturer produces prototypes of various steering system components for standard verification stages before mass manufacturing.

What are the requirements of a good steering system?

A good automotive steering system should have the following qualities:

- Smooth and easy to turn

- Stable

- Operates quietly

- Should have a perfect straight-line tracking

- Consistent responsive feedback

- Smooth automatic centering

What factors influence the material selection for steering system components?

When selecting material for steering system components, these points are the most critical: Strength-to-weight ratio, corrosion resistance, wear resistance, manufacturability, and reliability.

In Conclusion

The driver heavily relies on the steering system to get feedback about the road conditions. It is the means to give the car directional control. Quality steering is extremely important, considering that the system is also linked to suspension, traction control, and other features of the car.

The only way to ensure a car’s steering system operates at its prime level is to choose genuine parts designed and manufactured to operate at OEM standards.

ProleanTech runs a highly reputable CNC machining business in China and overseas, and can make custom automotive steering parts that stand the test of time. Ask for CNC Machining Services today to learn more about the capabilities.

Spotlight on this featured post—don’t miss the highlight of the week!