Table of Contents

- Introduction

- Enhanced Scalability and Flexibility

- Improved Collaboration and Communication

- Cost Efficiency and Resource Optimization

- Enhanced Data Security and Compliance

- Real-Time Monitoring and Predictive Maintenance

- Conclusion

Key Takeaways

- Cloud manufacturing software dramatically improves operational scalability and flexibility for enterprises of all sizes.

- Enhanced collaboration, cost efficiency, security, and predictive maintenance are core advantages.

- Adopting cloud-driven manufacturing solutions is increasingly essential for staying competitive in a digital economy.

Introduction

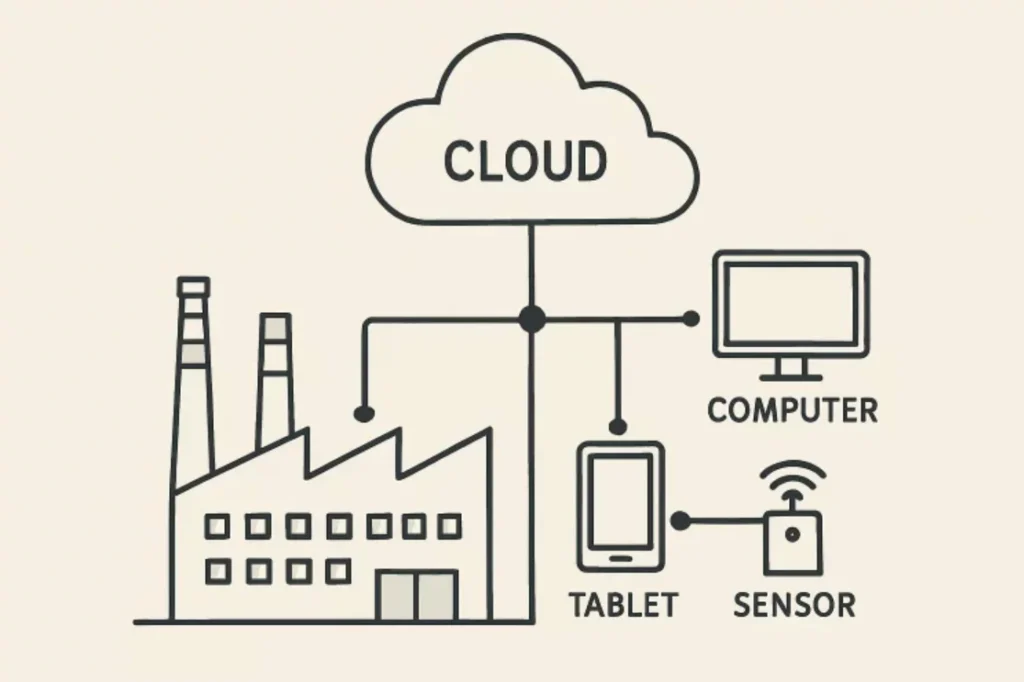

The manufacturing industry is undergoing rapid digital transformation, driven by the need for agility and innovation. Cloud manufacturing software has emerged as a critical tool, providing centralized and scalable solutions that replace outdated legacy systems. These platforms integrate people, processes, and data to streamline operations and improve responsiveness. As market conditions become more volatile, manufacturers are turning to the cloud for real-time insights and faster decision-making. This shift enables companies to build resilience, maintain competitiveness, and prepare for future growth.

Enhanced Scalability and Flexibility

Cloud manufacturing solutions provide unparalleled scalability and flexibility, enabling companies to adjust resources instantly without incurring significant hardware investments. This contrasts sharply with traditional systems, which are often costly and rigid. With market projections estimating growth from $72.2 billion in 2024 to $211.7 billion by 2032, it’s clear that demand for scalable, adaptable solutions is surging. Manufacturers benefit from faster time-to-market, simplified expansion, and the ability to manage fluctuating workloads efficiently. Additionally, seamless integration with both old and new systems allows organizations to innovate and grow strategically at their own pace.

Liked what you read? This related post is another hidden gem.

Improved Collaboration and Communication

Cloud manufacturing platforms centralize business-critical data, making it accessible to stakeholders across different locations. This fosters real-time collaboration, especially for companies managing global supply chains or multi-site operations. Teams such as design, production, and quality assurance can work simultaneously within a secure digital space. They can instantly communicate changes, co-develop prototypes, and align on project milestones. This streamlines workflows, shortens development timelines, and enhances decision-making across departments.

Accelerating Product Development

Digital unification eliminates data silos, enabling faster, more agile product development. Stakeholders from R&D to supply chain partners gain access to real-time updates and shared progress reports. This transparency boosts innovation and strengthens collaboration between manufacturers and external partners. Organizations can adapt quickly to customer demands and shifting market conditions. As a result, time-to-market improves and competitive positioning becomes stronger.

Cost Efficiency and Resource Optimization

Cloud manufacturing software offers significant cost savings by reducing the need for physical infrastructure. Through the SaaS model, companies only pay for the resources they actually use, avoiding waste. Cloud vendors handle system maintenance, updates, and cybersecurity, freeing internal IT teams to focus on strategic projects. This ensures continual access to the latest tools and features with minimal disruption. Overall, businesses gain operational agility while controlling IT expenses.

Optimizing Resource Allocation

Predictive analytics and detailed reporting tools enable manufacturers to track the utilization of resources. These insights enable better scheduling, improved asset utilization, and enhanced energy efficiency. Companies can reallocate budgets and staff toward high-impact tasks. This leads to increased production output and better financial planning. Aligning resources with strategic priorities fosters a lean, efficient, and performance-driven culture.

To further solidify this strategic alignment and optimize operations, many leading manufacturers are turning to specialized solutions. Platforms like manufacturing strategy alignment software provide comprehensive tools to manage inventory, reduce waste, and prevent shortages. These systems ensure that resource allocation is directly tied to overarching business objectives, driving efficiency and profitability. By integrating such software, businesses can gain a holistic view of their performance, enabling proactive decision-making and continuous improvement.

Enhanced Data Security and Compliance

Security is paramount in a digital manufacturing environment, where sensitive intellectual property is at stake. Cloud platforms provide robust protection, including encryption, real-time monitoring, and advanced threat detection. They also support compliance with global standards such as GDPR and ISO certifications. Regular third-party audits ensure continued trust and accountability. For highly regulated industries, cloud solutions provide the necessary transparency and documentation to meet strict legal requirements.

Reducing Risk and Liability

Using secure cloud infrastructure minimizes the risk of data breaches and operational disruptions. Centralized systems enable quick responses to compliance issues, quality events, or legal concerns. Audit trails offer accountability and simplify regulatory reporting. This reduces liability and helps protect the company’s reputation. Overall, cloud platforms create a stable environment that supports business continuity even in the face of challenges.

Real-Time Monitoring and Predictive Maintenance

IoT-enabled cloud platforms enable continuous monitoring of machinery and production systems. Real-time dashboards give managers up-to-the-minute insights into equipment status and performance. Predictive maintenance utilizes AI to identify wear or faults before they lead to breakdowns. This proactive approach reduces unplanned downtime and extends the lifespan of critical assets. Ultimately, it enhances productivity and lowers long-term operational costs.

Conclusion

Cloud-based manufacturing software represents a transformative shift in industrial operations. Its ability to scale, connect teams, and streamline costs gives companies a strategic edge. Built-in analytics, security, and compliance support enable safe and efficient workflows. These platforms enable businesses to stay agile and competitive in rapidly changing markets. Embracing cloud technology is now essential for long-term success in the manufacturing sector.

Want more insights like this? Head over to Management Works Media and start exploring.