Do your projects need clean metal cuts delivered on time?

Professional cutting services help shops keep work moving smoothly. They support daily production without slowing teams down. Reliable providers focus on steady results that meet real workplace needs.

This kind of support helps projects stay on track and on schedule. Read on to learn how the right service makes a difference.

Precision Cutting Needs

Accurate cuts make projects easier and reduce problems that could slow work. Services check each piece carefully and adjust whenever something seems off. Taking time with every cut ensures parts fit properly and stay ready for the next step.

Shops maintain machines and tools daily to keep the cutting process steady. Workers focus on details at every step to maintain consistent results for each task. Following careful routines allows operations to continue smoothly without mistakes or interruptions.

Precision requires constant focus and careful habits in daily work. Accurate work keeps the entire workflow organized and efficient for everyone involved.

How the Process Runs

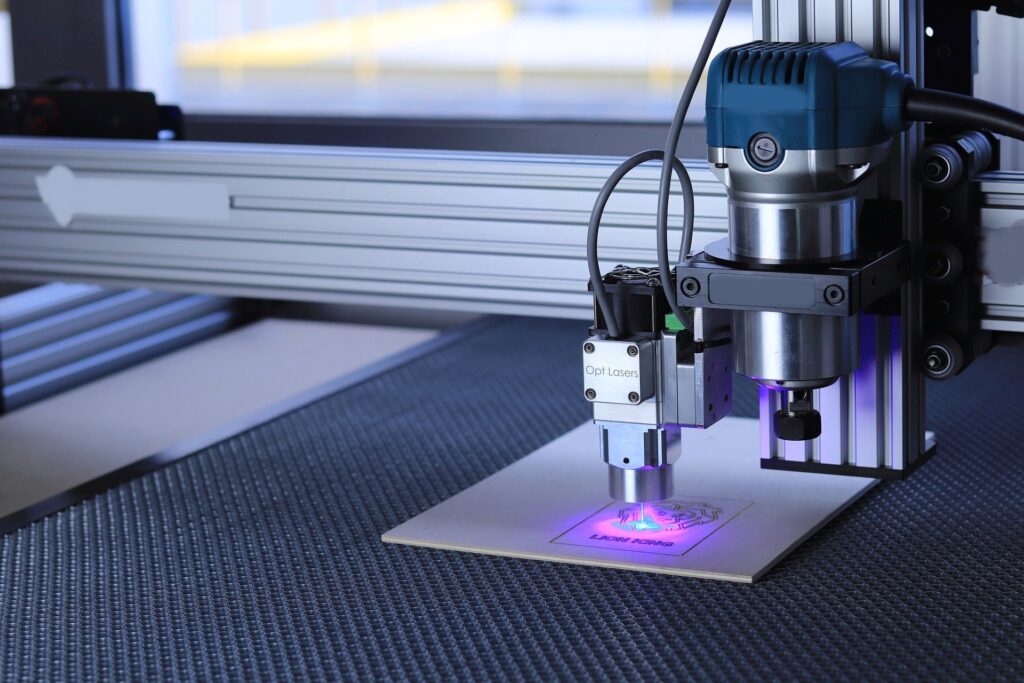

Laser cutting begins when machines heat up and focus on the exact spot needed. Operators guide the process to make sure each shape comes out correctly. The work moves steadily without rushing, so each piece is handled carefully.

The process uses careful settings to control speed and power for every job. Adjustments happen while the machine runs to keep results smooth and accurate. Workers watch closely to catch anything that might cause problems.

Following each step carefully ensures that the final product meets expectations and needs. Teams work together to keep everything moving without mistakes. The process may sound simple, but it takes attention to do it well.

Industrial Use Cases

Shops cut metal to meet project designs and requirements. Accurate parts fit together properly for machinery and finished products. Operations stay on schedule when every cut matches the plan exactly.

Many industries use clean, steady cuts to keep projects moving each day. Correct cutting prevents mistakes that slow work or require redoing pieces. Reliable processes help production continue without interruptions or stress.

Even small workshops gain efficiency when services handle each cut carefully. Shops plan and complete each task to meet production needs. Consistent work keeps operations organized and running smoothly throughout the day.

Metal Types Served

Shops handle many metals every day to meet different project needs. Teams focus on each piece and make sure cuts fit the plan. Using the right approach keeps work moving smoothly without slowing anyone down.

Workers often choose the proper laser cutting materials to get the best results. They check the thickness and strength before starting to keep everything accurate. Paying attention to these details saves time and keeps projects on track.

Every metal reacts differently when cutting, so teams adjust carefully as they work. They make sure edges stay clean, and shapes match exactly. Consistent care with each piece helps the shop run without interruptions or mistakes.

Production Flow Support

Services maintain steady production by following clear routines each day. They check every step to prevent errors that could slow work. Smooth workflows help shops operate efficiently and feel organized.

Workers handle tasks in ways that match the pace of the shop. They make small adjustments when issues appear to keep operations moving. Clear coordination ensures projects continue without unnecessary interruptions or confusion.

Planning and consistent work keep projects on track from start to finish. Services avoid rushing and prevent careless mistakes. Taking time with each task keeps production flowing calmly and efficiently.

Turnaround Time Value

Services focus on keeping turnaround time short to help projects finish on schedule. They plan each step carefully to avoid delays and mistakes. Following clear routines helps work move smoothly without slowing down operations.

Staff watch each job and make small adjustments while the work is happening. Services handle tasks in order so turnaround time stays as short as possible. Paying attention to timing prevents projects from taking longer than expected.

Managing turnaround time well gives operations a steady pace every day. Services make sure each task flows into the next without waiting. Good planning and consistent work keep projects moving from start to finish without problems.

Consistent Cut Results

Services ensure every cut matches specifications and the project plan. Operators inspect each piece and correct issues immediately. Accurate cuts help parts fit together without extra adjustments or rework.

Workers follow the same method for each task to maintain precision. They measure and check shapes before moving on to the next step. Careful work prevents mistakes that could disrupt daily operations.

Consistent cutting allows operations to continue confidently and efficiently. Accuracy reduces wasted time and prevents unnecessary stress. Maintaining high standards keeps projects on track from start to finish.

Choosing a Provider

It helps to think carefully before picking a service for your projects. You can ask questions about how they handle different metals and cutting shapes. Checking examples of past work shows the quality they can deliver.

Talk about your schedule and deadlines before work begins. Make sure the service can meet timing needs without rushing or cutting corners. Clear communication helps avoid confusion and keeps tasks running smoothly.

Pick a service that follows a careful and consistent process. Confirm they handle each step with attention to detail. Choosing the right service makes projects easier and keeps work moving without problems.

Ongoing Shop Support

Ongoing support helps the work keep moving without stopping or slowing down. Services check tools and set up materials so every task stays clear and ready to start. Regular help spots small problems early and fixes them before they grow bigger.

Staff can handle each task more easily when help is always close by. Services guide each step, answer questions quickly, and make adjustments while work continues. Paying attention every day keeps projects moving forward and running smoothly.

Steady support makes it possible to finish projects from start to finish. Work stays organized when every step receives careful and consistent attention. Ongoing help gives operations a steady pace and prevents mistakes or delays.

Always Go for Professional Laser Metal Cutting Services

Every project ends, and each day of work adds up. Finishing tasks well matters for everyone involved. Handling each step carefully helps everything fall into place. Paying attention to each detail makes the outcome feel complete and organized.

Even small actions shape how the work is remembered and built upon. Wrapping up with care gives a sense of order and readiness for what comes next.

Did you find this post helpful? If so, head back to our website for more informative content.