Quality control is changing fast in today’s industries. Companies now need better ways to check accuracy and reduce errors. This is where 3D technology plays a major role.

It helps businesses inspect products with speed and precision. By using digital models instead of manual checks, quality control becomes smarter and more reliable.

As competition grows, companies must deliver better products in less time. 3D technology helps them meet these demands with confidence.

Understanding 3D Technology in Quality Control

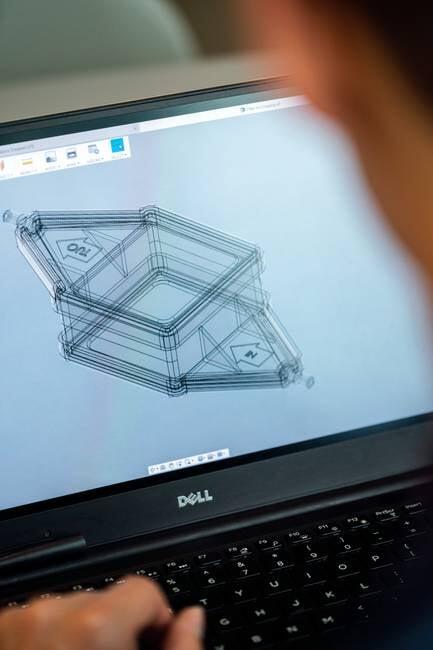

3D technology captures the exact shape and size of an object. It creates a digital model that represents the real item. This model can then be measured, tested, and compared to design standards.

Common 3D tools include scanners, sensors, and cameras and these tools collect thousands or even millions of data points. The result is a detailed image that shows even small defects and this level of detail is hard to achieve with traditional methods.

By using digital data, inspectors can repeat tests and track changes over time. This makes quality control more consistent and easier to manage. It also allows teams to rely on facts instead of guesswork.

Faster Inspections and Shorter Production Times

Speed is one of the biggest advantages of 3D technology. Traditional inspections often require stopping production. Workers must measure parts one by one using manual tools and this process can slow down operations and increase delays.

3D systems can scan objects in seconds. Many inspections can happen directly on the production line. This reduces downtime and keeps work moving without interruption.

Faster inspections also mean quicker decisions. If a defect appears, teams can fix the issue early and this prevents large batches of faulty products. Over time, this speed improves overall efficiency and productivity.

Higher Accuracy and Reduced Human Error

Human error is a common challenge in quality control. Even skilled inspectors can miss small flaws. Fatigue and time pressure can also affect results.

3D technology reduces these risks. Automated systems follow the same process every time and they do not get tired or distracted. Measurements remain consistent across different shifts and locations.

High accuracy is especially important for industries like aerospace, automotive, and medical devices. In these fields, even small defects can cause serious problems. 3D inspections help ensure safety and reliability.

Better Detection of Hidden Defects

Some defects are hard to see with the naked eye. These include surface irregularities, warping, or small cracks. Traditional tools may not detect these issues during routine checks.

3D scans capture full surface data and they reveal hidden problems that might go unnoticed otherwise. Inspectors can rotate and zoom into the digital model. This allows them to study areas that are hard to reach physically.

In industries where precision matters, this ability is crucial. It leads to higher product quality and fewer failures in real-world use.

Improved Documentation and Traceability

Quality control is not just about finding defects. It also involves keeping accurate records. Companies need proof that products meet standards and regulations.

3D technology creates digital records automatically. Each scan becomes part of a data archive. These records can be stored, shared, and reviewed at any time without loss of detail.

This improves traceability. If an issue appears later, teams can review past scans. They can identify when and where the problem started. This makes problem-solving faster and more effective.

Supporting Custom and Complex Designs

Modern products are becoming more complex. Custom designs and unique shapes are now common across many industries. Traditional measurement tools struggle with these forms.

3D technology handles complexity with ease. It captures free-form shapes and detailed geometries. This makes it ideal for custom parts and prototypes.

For example, companies offering services like 3d laser scanning in Toronto often support industries working with complex structures. These scans ensure that unique designs still meet strict quality requirements.

Cost Savings Over Time

At first, 3D technology may seem expensive. Equipment and training require investment. However, the long-term savings are significant for most businesses.

Fewer defects mean less rework and scrap. Faster inspections reduce labor costs. Early detection prevents costly recalls and repairs that can harm a company’s reputation.

Over time, these benefits outweigh the initial costs. Many companies see a strong return on investment. Quality control becomes not only better but also more affordable.

Real-Time Feedback and Process Improvement

3D systems can provide real-time data. This means teams receive feedback during production, not after it ends.

With real-time insights, adjustments can happen immediately. Machines can be recalibrated, and processes can be refined on the spot. This leads to continuous improvement.

Data from 3D inspections also helps managers make informed decisions. Trends and patterns become easier to spot. This supports smarter planning and better quality strategies.

Integration With Digital Workflows

Many industries are moving toward digital workflows. 3D technology fits well into this environment and supports automation.

Scans can integrate with design software and quality management systems. This creates a seamless flow of information from design to production to inspection.

Such integration reduces manual data entry. It also improves communication between teams. Everyone works from the same accurate data set, which reduces confusion.

Training and Workforce Benefits

3D quality control tools are often easier to use than traditional methods. Modern software includes clear visuals and guided steps.

This reduces training time for new employees. Workers can learn faster and perform inspections with confidence. Clear digital models also make results easier to understand.

The technology also supports experienced workers. It gives them better tools to do their jobs well. This improves job satisfaction and overall performance.

Challenges and Considerations

While 3D technology offers many benefits, it is not without challenges. Companies must choose the right tools for their needs. Not every system suits every industry or budget.

Data management is another consideration. Large scans create large files. Businesses need proper storage and security solutions to protect this data.

Training and change management are also important. Teams must adapt to new workflows and tools. With proper planning, these challenges can be managed successfully.

All About 3D Technology

3D technology is transforming quality control across many industries. It brings speed, accuracy, and reliability to inspection processes. Companies can detect defects earlier and improve overall product quality.

As products become more complex, traditional methods fall short. 3D solutions provide the precision needed for modern standards. They also support digital workflows and continuous improvement.

Visit our blog for more insights on technology, innovation, and quality control.