Glass is a remarkable material, used in everything from our windows to our smartphones. Yet, not all glass is created equal. While standard, or annealed, glass can shatter into dangerous shards upon impact, a much stronger and safer alternative exists. This material, known as tempered glass, has become a cornerstone of modern construction and product design. Understanding its unique properties helps explain why so many architects, builders, and product designers rely on trusted tempered glass manufacturers to supply this essential safety material for countless applications.

This article will explore the world of tempered glass. We will define what it is, detail its creation process, and highlight its significant benefits. You will also learn about its wide range of applications and understand why it is considered a superior choice for safety and durability.

Understanding Tempered Glass

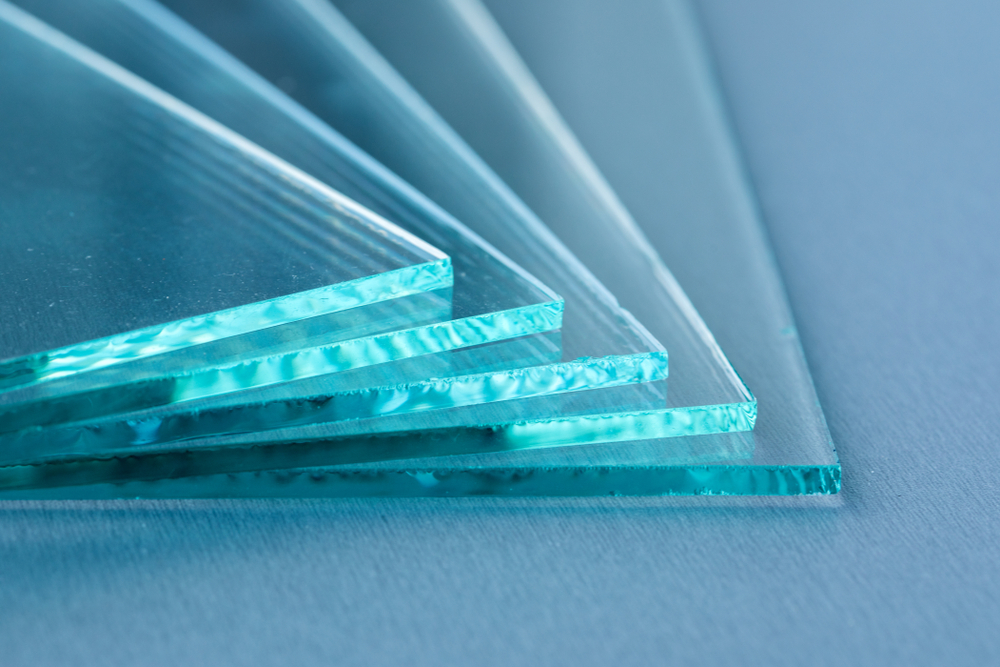

Tempered glass, often called “safety glass,” is a type of glass processed by controlled thermal or chemical treatments to increase its strength compared with normal glass. This tempering process creates a unique internal stress pattern. The outer surfaces are put into compression while the interior remains in tension. This balanced stress distribution is the secret to its enhanced strength and its characteristic way of breaking.

Unlike standard annealed glass, which breaks into large, jagged, and extremely sharp pieces, tempered glass is designed to crumble into small, granular, and relatively harmless chunks when it shatters. This property significantly reduces the risk of injury, making it a mandatory material in many safety-critical applications around the world.

The Manufacturing Process: From Fragile to Fortified

The transformation from standard glass to tempered glass is a fascinating display of material science. The process requires precision, control, and specialized equipment. It can generally be broken down into a few key stages.

1. Preparation and Cutting

The journey begins with a sheet of standard annealed glass. This raw glass is first inspected for any imperfections, such as bubbles or inclusions, that could cause it to break during the tempering process. Once approved, it is cut to the desired final size and shape. Any required drilling, edge grinding, or etching must also be completed before tempering. It is critical to perform all fabrication work at this stage because tempered glass cannot be cut or altered after the heating process without shattering.

2. The Heating Furnace

Next, the prepared glass sheet is moved into a tempering furnace. Inside, the glass travels on a roller system through a furnace that heats it to a uniform temperature of over 600 degrees Celsius (approximately 1,112 degrees Fahrenheit). The heating must be precise and evenly distributed across the entire surface of the glass to prevent the development of weak spots. This high temperature brings the glass to its softening point but does not melt it.

3. Rapid Cooling (Quenching)

Immediately after leaving the furnace, the glass undergoes a rapid and high-pressure cooling process known as “quenching.” During this stage, which lasts only a few seconds, high-pressure air nozzles blast cold air onto both surfaces of the glass simultaneously. This rapid cooling causes the outer surfaces of the glass to cool and solidify much faster than the center. As the interior cools more slowly, it pulls on the solidified outer surfaces, creating a state of high compression on the surface and tension in the core. This internal stress is what gives tempered glass its strength.

Key Benefits of Using Tempered Glass

The unique manufacturing process imparts several distinct advantages to tempered glass, making it a preferred material for numerous uses.

Enhanced Strength and Durability

The primary benefit is its impressive strength. Tempered glass is approximately four to five times stronger than standard annealed glass of the same thickness. This allows it to withstand higher levels of impact and pressure, making it far more resistant to breakage from blunt force, wind, or minor collisions.

Superior Thermal Resistance

The tempering process also makes the glass more resistant to thermal shock. It can endure significant temperature differences across its surface without fracturing. Tempered glass can typically handle temperature differentials of up to 250°C (482°F), whereas standard glass might crack with a change of just 40°C (104°F). This makes it ideal for applications like oven doors and laboratory equipment.

Unmatched Safety

Perhaps the most crucial benefit of tempered glass is its safety feature. When it does break, it crumbles into small, pebble-like pieces that lack sharp edges. This fracture pattern drastically reduces the likelihood of serious cuts and injuries, which is why it is legally mandated for certain applications like passenger vehicle windows, shower doors, and glass tabletops.

Common Applications of Tempered Glass

Thanks to its combination of strength, safety, and thermal resistance, tempered glass is used in a wide array of commercial, residential, and industrial settings.

Automotive Industry

Tempered glass is used for the side and rear windows of most vehicles. In the event of an accident, this ensures that the glass shatters into safe, blunt pieces, protecting passengers from serious injury. (Note: Windshields are typically made of laminated glass, which is a different type of safety glass.)

Architecture and Construction

In buildings, tempered glass is essential for safety glazing applications. You can find it in:

- Doors and Windows: Especially in storm doors, patio doors, and large picture windows that could be subject to impact.

- Shower and Tub Enclosures: A standard safety requirement to prevent injury in slippery environments.

- Staircase Railings and Balconies: Providing a secure barrier without obstructing views.

- Skylights and Glass Facades: Offering durability against weather and potential impacts.

Consumer Products and Appliances

Tempered glass is also a popular choice for many household items, including:

- Oven Doors and Cooktops: Its thermal resistance is critical for these high-heat applications.

- Refrigerator Shelves: Providing strong, easy-to-clean surfaces capable of holding heavy items.

- Screen Protectors: Used for smartphones and tablets to protect the device’s screen from scratches and impacts.

- Furniture: Commonly found in glass tabletops, shelves, and cabinet doors.

A Material Built for Strength and Safety

Tempered glass is more than just strong glass; it is an engineered material designed for safety and resilience. Through a controlled process of extreme heating and rapid cooling, standard glass is transformed into a durable product that can withstand significant stress. Its unique ability to break into small, harmless granules provides peace of mind and protection in our homes, vehicles, and public spaces. The next time you step into a modern shower, look out a patio door, or even glance at your phone’s screen protector, you can appreciate the science and safety engineered into that simple sheet of tempered glass.