Most poultry processors can recall at least one batch that looked perfectly fine leaving the line, only to turn into a headache once it hit distribution. And more often than not, the issue doesn’t start in cutting rooms or chillers. It starts in the packaging area—where moisture, microbial load, and shifting product collide in ways even the best upstream hygiene can’t fully control. One small sealing flaw is all it takes for a leak, a cold-chain failure, or a regulatory concern to surface.

What makes these failures so tricky is how quietly they develop. A piece slides out of place, film stretches a little too far, or temperatures drift for a few seconds—tiny deviations that don’t look like trouble during production but quickly become liabilities on the shelf. For high-volume plants, a one-percent defect rate isn’t an abstract statistic; it can mean thousands of compromised packs in a single shift.

That reality is pushing many processors to think of packaging not as a final step, but as a critical food-safety barrier. And this is where thermoforming technology begins to offer advantages traditional systems can’t reliably match.

Discover insights you won’t want to miss—check out this related post today!

The Real Sources of Contamination in Poultry Processing Lines

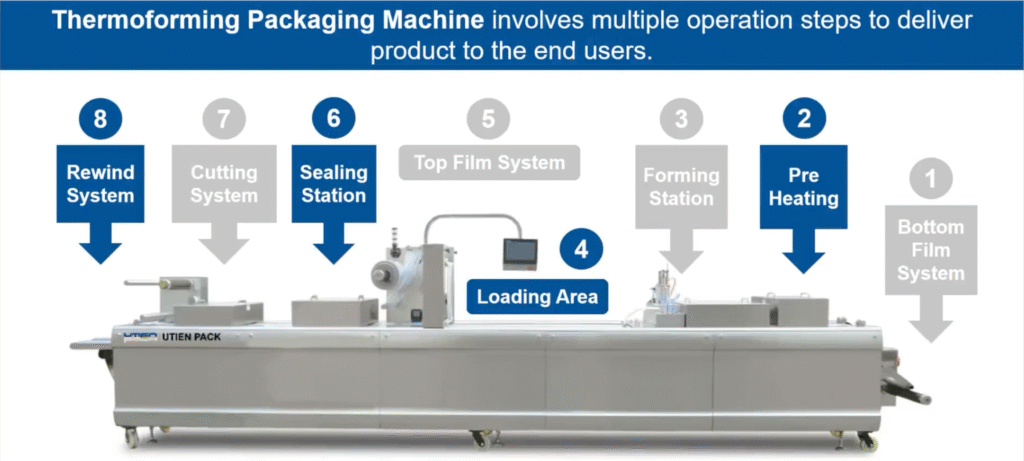

Most contamination problems in poultry packaging don’t stem from dramatic equipment failures. They build gradually from small, often unnoticed weak points. Any time a process relies on manual interventions—adjusting pieces, repositioning product, or making small corrections—variability enters the system. Thermoforming packaging lines significantly cut down these touchpoints by elevating automation throughout the forming and sealing process. The result is a cleaner, more consistent workflow with far fewer opportunities for human error to influence safety outcomes.

Temperature drift during staging is another quiet threat. Poultry that sits outside ideal temperature ranges, even briefly, gives microorganisms more time to multiply before the product is sealed. On a fast-moving line, these small lapses are easy to miss but have real downstream impact.

Irregular cuts—wings, drumsticks, mixed pieces—add complexity of their own. Uneven height profiles stretch film unpredictably, creating micro-channels that pass visual inspection but fail under transport vibration. And because poultry holds so much moisture, any inconsistency in forming tension or sealing temperature increases the chance of leaks.

Individually, each issue looks minor. Together, they create the conditions behind most leakage, spoilage, and shelf-life failures.

How Thermoforming Packaging Machines Control These Risk Factors

Thermoforming systems address these weak points head-on. By carrying out key packaging steps within a stable, automated environment, thermoforming technology greatly reduces the variability introduced by manual interaction. This controlled process minimizes the small inconsistencies that often lead to surface contamination or compromised seals.

Forming precision is another advantage. Poultry pieces vary widely in shape and size, yet thermoforming equipment creates consistent pockets that support and stabilize these irregularities. This reduces film stress—especially around bones, where leaks often start. With stable film tension and uniform heat distribution, sealing becomes far less sensitive to moisture or shape variation.

Processors needing deeper microbial control can integrate vacuum packaging, Modified Atmosphere Packaging (MAP), or Vacuum Skin Packaging (VSP) into a single thermoforming packaging machine. Lower oxygen exposure and tighter containment create more predictable safety performance throughout the distribution chain.

Why Poultry Products Benefit More From Thermoforming Than Other Proteins

Poultry brings a mix of challenges that thermoforming handles unusually well. High moisture content means drip is a constant concern, and any weakness in package geometry can quickly become a sealing failure. Deep, stable forming pockets help contain fluids and reduce pressure points that cause leaks in traditional formats.

Irregular cuts settle more reliably into thermoformed cavities. Wings, drumsticks, and uneven portions sit naturally in uniform shapes, reducing film strain during sealing and transport. For marinated products, the benefit is even clearer—thermoforming keeps sauces and seasonings from creeping into seal zones, one of the most common triggers of seal contamination.

Processors who want to evaluate how these advantages fit their operations can click here to explore a poultry packaging solution tailored for high-moisture, irregular-shaped products.

Choosing the Right Packaging Approach for Each Poultry Application

Different poultry SKUs place different demands on a packaging line. Fresh cuts usually perform best in vacuum or MAP environments, where oxygen control supports microbial stability and temperature integrity. Marinated items need stronger, more reliable sealing to manage liquid movement and keep seasoning from interfering with the seal.

Frozen poultry introduces a different challenge. Low temperatures stiffen films and can cause cracking if forming and sealing aren’t consistent. Retail-ready cuts benefit from VSP’s second-skin look, which minimizes visible drip and enhances presentation. When the packaging method fits the product, safety and quality become far more predictable.

How to Select the Right Thermoforming Setup for Your Poultry Line

Choosing a thermoforming setup is less about comparing machine specifications and more about aligning equipment with real production needs. High-volume operations often prefer rollstock systems for their deeper forming, faster cycles, and integration options—such as in-line seal inspection or metal detection. Smaller or flexible plants may choose compact units that offer easier changeovers without sacrificing seal quality.

Vacuum, MAP, and VSP each support different product and logistics profiles. Vacuum suits tighter distribution networks; MAP stabilizes fresh poultry; and VSP elevates premium cuts. Film selection is equally important—moisture-heavy products need stronger barrier materials and consistent forming behavior to prevent deformation.

Processors get the best results when machine choice, film properties, and product characteristics are evaluated together instead of treated as separate decisions.

The Future of Poultry Safety: Automation and Real-Time Control

Safety expectations are rising, and packaging lines are evolving with them. Real-time seal inspection and automated leak detection catch issues that manual checks routinely miss. Advances in mono-material films add sustainability without compromising performance. Meanwhile, hands-free loading systems reduce contamination points and ease the strain on labor.

Packaging is no longer just the final station—it’s becoming one of the strongest safety controls in poultry processing. For plants handling moisture-heavy, shape-variable products, thermoforming doesn’t just improve appearance; it adds the consistency and predictability that modern food-safety programs increasingly depend on.

Highlight of the week: See why this featured post is grabbing attention!