Die-cut products are essential for precision cutting in the packaging, electronics, medical devices, clothing, apparel, and automotive industries Die Cutting Methods.

As not all projects are alike in their accuracy, pressure, and material hold-down requirements for cutting, there are several methods of cutting to obtain that perfect finish. Read on as you find out about five essential die-cutting techniques.

Related posts ahead—carefully chosen to enhance your reading experience.

1. Flatbed Die Cutting

Diecutting on a flatbed is also well-known for its durability and adaptability. Because a steel-rule cutting die and a vertical press are used to apply pressure, the system can cut thicker materials like rubber, foam, fibreboard, or hard plastic.

Due to the versatility of the material, manufacturers are able to achieve clean shapes without compromising its strength.

It is also possible to use flatbed cutting for multi-layer applications because of the even pressure that it provides. It’s a word that can be used when durability is important, especially for industrial or structural parts that need to work no matter where the acids, bases, and salts come from.

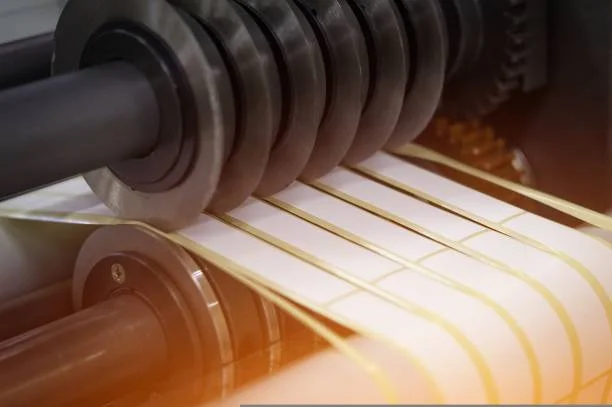

2. Rotary Die Cutting

Large rotating drums are utilised in the rotary die cutters in order to cut materials as they move through the machine. When it comes to cutting large quantities of material, this is especially of great assistance.

Because of its compatibility with flexible materials like films, paper, nonwoven, or very thin plastic film, it is also frequently used for mass production. Less downtime resulting from the constant movement of the cylinders means operators and businesses can move faster to complete high-volume orders.

3. Laser Die Cutting

In laser die-cutting, powerful lasers are used to cut the material, rather than mechanical dies. This is finding its way to very sharp, clean-edged shapes. This technique is especially useful when cutting delicate shapes or intricate patterns that may otherwise be ruined.

As a digital process, laser die cutting is very versatile. Businesses can rapidly adjust digital files to get a design into production, instead of having to physically create a die for each new design.

4. Kiss Cutting

Labels, decals and stickers, as well as items that can retain their form but are liable to pressure change, such as bumpers, pads and gaskets, are all suitable for kiss cutting. If you do need to take your product off, it is easier than ever to remove the material and apply it to a new location in order for you to install your item.

It will also save you time, which is a significant benefit. As a result, it will not be broken when it is placed on a sander because the back surface of the object has not been prepared for cutting. This wrinkled sheet makes it so that dust particles and material do not stick to the wall, and you can change the sheets without difficulty.

5. Water Jet Cutting

Water jet cutting slices materials with a high-powered stream of water, but without any heat. This aspect is particularly important when screening for materials that will warp, melt, or burn at higher temperatures. This method applies to foam, rubber, fabric, and some plastics.

Precision is another advantage. The computer-controlled water jets come in when manufacturers want to create detailed designs without warping the material too much.

With Die cutting services or Die Cutting Methods, vendors also guarantee the availability of appropriate tools, machines, and technical know-how. And their knowledge of materials drives the cutter to use a cutting method that works for every application, thereby enhancing speed and final product quality.

Choosing the Right Cutting Method

Die cutting isn’t just about trimming; it’s a process that shapes items with precision and purpose. By using the optimal process for each material or Die Cutting Methods, manufacturers are able to fabricate parts that exceed the highest-performance specifications.

Explore more to unlock fresh ideas, trends, and expert insights at Management Works Media.